Summary of Contents for Canon LBP6670dn Series

-

Page 1: Service Manual

LBP6670dn/6680x Series Service Manual Product Description Technology Disassembly/Assembly Maintenance and Inspection Trouble Shooting F-0-1 Appendex... - Page 2 Canon Inc. arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition (C) CANON INC.

- Page 3 Explanation of Symbols The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the The following symbols are used throughout this Service Manual. relationship between electrical and mechanical systems with reference to the timing of operation.

-

Page 4: Table Of Contents

Contents Laser Exposure System -----------------------------------------------------2-3 Outline -------------------------------------------------------------------------------- 2-3 Optical Unit Failure Detection --------------------------------------------------- 2-3 Image Formation System ---------------------------------------------------2-4 Outline -------------------------------------------------------------------------------- 2-4 Safety Precautions Image Formation Process ------------------------------------------------------- 2-4 Safety Information ------------------------------------------------------------0-6 Outline ----------------------------------------------------------------------------------------- 2-4 Latent image formation block ------------------------------------------------------------ 2-5 Laser Safety ------------------------------------------------------------------------- 0-6 Developing block---------------------------------------------------------------------------- 2-5 CCDRH Regulation ---------------------------------------------------------------- 0-6... - Page 5 Outline ----------------------------------------------------------------------------------------2-15 Enhanced System Application Management-------------------------------2-45 Motor control --------------------------------------------------------------------------------2-16 Outline ----------------------------------------------------------------------------------------2-45 Fan control ----------------------------------------------------------------------------------2-17 About Login Service-----------------------------------------------------------------------2-45 Failure Detection ---------------------------------------------------------------------------2-17 Default Authentication overview--------------------------------------------------------2-45 Low-voltage Power Supply -----------------------------------------------------2-17 Other Log in service-----------------------------------------------------------------------2-45 Outline ----------------------------------------------------------------------------------------2-17 Procedure Changing Login Services -------------------------------------------------2-45 Protective function -------------------------------------------------------------------------2-18 Procedure Installing Login Services --------------------------------------------------2-46 Safety -----------------------------------------------------------------------------------------2-18 Procedure Uninstalling Login Services -----------------------------------------------2-47...

- Page 6 Embedded RDS ------------------------------------------------------------- 2-61 Removing the Main Controller Board ----------------------------------------3-12 Product Overview -----------------------------------------------------------------2-61 Actions before Replacement ------------------------------------------------------------3-12 Removing the Main Controller Board -------------------------------------------------3-12 Overview -------------------------------------------------------------------------------------2-61 Actions before Replacement (LBP6670 only) --------------------------------------3-13 Features and benefits --------------------------------------------------------------------2-61 Remove the Sleep Interface PCB --------------------------------------------3-14 Service cautions -------------------------------------------------------------------2-62 Remove the Duplex Reverse Sensor Unit ----------------------------------3-14 E-RDS Setup -----------------------------------------------------------------------2-62...

- Page 7 Periodical Service ------------------------------------------------------------------ 4-2 Limitations and Cautions-----------------------------------------------------------------5-20 Preparation ----------------------------------------------------------------------------------5-21 Cleaning -------------------------------------------------------------------------4-2 System Management Operations------------------------------------------------------5-27 Cleaning at Service Visit --------------------------------------------------------- 4-2 a. UGW-linked Download and Update (Full-remote Update) -------------------5-30 Trouble Shooting b. UGW-linked Download (Remote Distribution Update) ------------------------5-30 Deleting the Scheduled Firmware Delivery -----------------------------------------5-31 Trouble Shooting --------------------------------------------------------------5-2 Updating the Downloaded Firmware (Application of Firmware) ---------------5-31 Test Pages --------------------------------------------------------------------------- 5-2...

- Page 8 Special Tools --------------------------------------------------------------------------- II Solvents and Oil List ----------------------------------------------------------------- II General Timing Chart ----------------------------------------------------------III General Timing Chart ------------------------------------------------------------------------ III General Circuit Diagram ------------------------------------------------------ IV General Circuit Diagram ----------------------------------------------------------- IV Backup Data ---------------------------------------------------------------------- V...

-

Page 9: Safety Precautions

Safety Precautions ■ L aser Safety ■ C CDRH Regulation ■ T oner Safety ■ O zone Safety ■ H ow to Handle the Laser Scanner Unit ■ P oints to Note when Replacing/Discarding a Lithium Battery ■ P oints to Note when Performing Disassembly/Assembly... -

Page 10: Safety Information

Safety Precautions > Safety Information > Ozone Safety 0-10 Safety Information Toner Safety ■ About Toner Laser Safety Toner is a nontoxic substance which consists of plastic, iron, and a small amount of pigment. Laser beam radiation sometimes causes a danger to human body. To prevent such a danger, CAUTION: the optical laser system used in this machine is hermetically closed by the protection housing and external cover so that a laser beam does not leak to outside. -

Page 11: How To Handle The Laser Scanner Unit

Safety Precautions > Safety Information > Points to Note when Performing Disassembly/Assembly 0-11 How to Handle the Laser Scanner Unit Points to Note when Performing Disassembly/Assembly An invisible laser beam is irradiated in the laser scanner unit. Be sure to follow the instruction shown below when performing disassembly/assembly. If the laser beam enters an eye, it may cause damage to the eye. -

Page 12: Product Description

Product Description ■ Product Lineups ■ Features ■ List of Parts ■ Operation Product Description... -

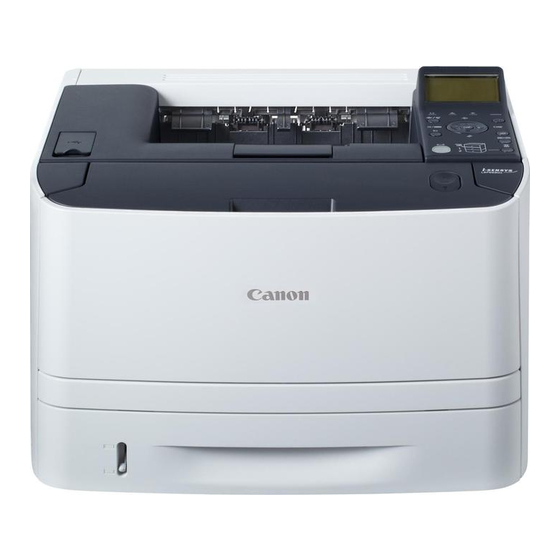

Page 13: Main Unit

Product Description > Features Product Lineups Features 1. Small and high-speed printer Main unit The printer is compact size that realizes print speed of approximately 35 pages per minute on letter-size media and approximately 33 pages per minute on A4-size media by i-SENSYS Function LBP6670 LBP6680... -

Page 14: Specification

Product Description > Specification > Printing Speed Specification Item Specification/function LBP6670 LBP6680 Hard Disk Capacity Standard: None, Option: None Product Specifications Ambient Temperature Range for Use 10 to 30 degrees Celsius Ambient Humidity Range for Use 20 to 80% RH Operation Noise Level 53.5 dB or less (During printing: rated sound emission level Item... -

Page 15: List Of Parts

Product Description > List of Parts > Cross Sectional View List of Parts Cross Sectional View External View [10] [11] [12] [13] [14] [10] [11] [12] [13] [14] [15] [16] [15] [17] [16] [17] [20] [19] [18] F-1-2 Name Name Fixing Delivery Roller [11] Multi-purpose Tray Pickup Roller... -

Page 16: Operation

Product Description > Operation > Control panel Operation Name Function When the printer is online When the When the menu is Control panel printer is offline displayed [5] Status/Cancel Key If pressed when the Job indicator is on or Does not function. blinking (When data is being processed or received), diaplay the job list. -

Page 17: Technology

Technology ■ Basic Operation ■ Sequence of Operation ■ Laser Exposure System ■ Image Formation System ■ Fixing System ■ Pickup Feeding System ■ Controller System ■ MEAP ■ Embedded RDS Technology... - Page 18 Technology > Sequence of Operation > Outline Basic Operation Sequence of Operation Function Structure Outline The function structure of the printer contains the following five systems: The operation sequence is controlled by the DC Controller in the engine control system. •...

-

Page 19: Outline

Technology > Laser Exposure System > Optical Unit Failure Detection Laser Exposure System Optical Unit Failure Detection The optical unit failure detection manages the laser scanner failure detection functions. Outline The DC controller determines an optical unit failure and notifies E100 to the Main controller if the laser scanner encounters the following conditions: The laser exposure system forms a latent image on the photosensitive drum according to the •... -

Page 20: Image Formation System

Technology > Image Formation System > Image Formation Process > Outline Image Formation System Image Formation Process Outline ■ Outline The image formation process consists of the following seven steps divided among five The image formation system forms a toner image on print media. functional blocks: The following are the main components of the image formation system: •... -

Page 21: Latent Image Formation Block

Technology > Image Formation System > Image Formation Process > Developing block ■ Latent image formation block ■ Developing block During the two steps that comprise this block, an invisible latent image is formed on the Toner adheres to the electrostatic latent image on the photosensitive drum, which becomes photosensitivedrum. -

Page 22: Transfer Block

Technology > Image Formation System > Image Formation Process > Drum cleaning block ■ Transfer block ■ Fixing block During the two steps that comprise this block, a toner image on the photosensitive drum is The toner image is fixed onto the print media. transferred to the print media. -

Page 23: High-Voltage Power Supply

Technology > Image Formation System > High-voltage Power Supply > Outline High-voltage Power Supply ■ Outline The high-voltage power supply applies biases to the following components: • Primary charging roller • Developing roller • Transfer roller • Fixing film The DC controller controls the high-voltage power supply to generate biases. See "IV. IMAGE-FORMATION SYSTEM"(Refer to page 2-4)for detailed information. -

Page 24: Outline

Technology > Fixing System > Outline Fixing System Outline Fixing unit The fixing/delivery unit fixes the toner onto a print paper and delivers it to the delivery tray. The operation of the fixing/delivery unit is explained in the following. Fixing film 1) The print paper fed from the pick-up/feed unit is fused the toner by the fixing film and the pressure roller. -

Page 25: Fixing Control Circuit

Technology > Fixing System > Fixing control circuit > Small Size Paper Printing Speed Control (Throughput Reduction Control) Fixing control circuit ■ Small Size Paper Printing Speed Control (Throughput Reduction Control) The fixing control circuit controls the temperature in the fixing unit. The printer uses an on- demand fixing method. -

Page 26: Fixing Temperature Control

Technology > Fixing System > Fixing control circuit > Protective function 2-10 ■ Fixing temperature control heater control circuit controls the fixing heater depending on the signal so that the heater remains at the targeted temperature. The fixing temperature control maintains the temperature of the fixing heater at its targeted temperature. -

Page 27: Failure Detection

Technology > Fixing System > Fixing control circuit > Failure detection 2-11 ■ Failure detection The DC controller determines a fixing unit failure, makes the FIXING HEATER CONTROL signal inactive, releases the relay to interrupt power supply to the fixing heater and notifies the Main Controller of a failure state when it encounters the following conditions: 1) Start-up failure (E000) •... -

Page 28: Pickup Feeding System

Technology > Pickup Feeding System > Outline 2-12 Pickup Feeding System Diagram and table of the electrical components are shown below. Outline The pickup feeding system picks up, feeds and delivers the print media. It consists of several types of rollers. The duplex feed unit in the duplex model reverses and refeeds the print media to print on both sides of media. -

Page 29: Outline

Technology > Pickup Feeding System > Jam Detection > Reverse Delay Jam 2-13 Jam Detection ■ Pickup Delay Jam When the TOP Sensor (PS912) cannot detect the leading edge of paper within the specified Outline ■ time after starting pickup from a cassette, pickup retry is executed twice. After that, the sensor The printer uses the following sensors to check whether media is being fed correctly or has still cannot detect the leading edge of paper within the specified time, it is judged as a pickup jammed:... - Page 30 Technology > Pickup Feeding System > Jam Detection > Door Open Jam 2-14 ■ Reverse Stationary Jam When the Duplex Reverse Sensor (PS917) cannot detect the trailing edge of paper after the specified time has passed since the sensor detected the leading edge of paper, it is judged as a reverse stationary jam.

-

Page 31: Controller System

Technology > Controller System > DC Controller > Outline 2-15 Controller System DC Controller ■ Outline Outline The DC controller controls the operational sequence of the printer. The controller system controls all the other systems according to commands from the Main Block diagram of the DC Controller and table of the electrical components are shown below. -

Page 32: Motor Control

Technology > Controller System > DC Controller > Motor control 2-16 ■ Motor control Symbol for component Component Main Fan The printer has one motor for media feed and image formation. Motor Main Motor Arrangement of motor and the specifications are shown below. Solenoid Multi-purpose Tray Pickup Solenoid Cassette Pickup Solenoid... -

Page 33: Fan Control

Technology > Controller System > Low-voltage Power Supply > Outline 2-17 Low-voltage Power Supply ■ Fan control The printer has one fan for preventing a temperature rising inside the printer. ■ Outline Arrangement of fan motor and the specifications are shown below. The low-voltage power supply converts AC power from the power receptacle into DC power to cover the DC loads. -

Page 34: Protective Function

Technology > Controller System > Energy Saving Function 2-18 Energy Saving Function ■ Protective function The low-voltage power supply has a protective function against overcurrent and overvoltage This machine is equipped with energy saving function. to prevent failures in the power supply circuit. If there flows an overcurrent or an overvoltage, The following shows energy saving status and condition of transition. -

Page 35: Meap

Technology > MEAP > About MEAP > Overview 2-19 MEAP About MEAP ■ Overview Introduction MEAP (Multifunctional Embedded Application Platform) is an application platform (execution ■ References by purpose platform) that allows the user to execute an application written in the Java language on a Java virtual machine installed on the device. -

Page 36: About Sms

Technology > MEAP > About SMS > About the MEAP Application Installation Screen 2-20 About SMS ■ About the MEAP Application Management Screen This screen is used to perform basic management of MEAP applications. Its main functions ■ Overview are listed below. MEAP has SMS (Service Management Service) as a service for managing login services and •... -

Page 37: About System Management

Technology > MEAP > Preparation for Using SMS > Preparation of PC for Accessing SMS 2-21 Preparation for Using SMS ■ About System Management It is used to perform MEAP management other than management of MEAP applications and To use SMS, you need to set up network settings for the PC, browser, and devices that are installation of MEAP applications. -

Page 38: Device Settings

Technology > MEAP > Preparation for Using SMS > Device Settings 2-22 ■ Device Settings ● Key Pair and Server Certificate when Using Encrypted SSL Communication ● Network configuration ( Activate Netowork Settings ) To use SMS via SSL connection, it is required to specify a key pair and server certificate as To support a MEAP-enabled iR device via network (SMS, etc.), set up the network setting on the key to be used. - Page 39 Technology > MEAP > Preparation for Using SMS > Device Settings 2-23 2) Click [ Management Settings ] > [ Security ] > [ Key and Certificate Settings ]. 4) Enter the necessary information, and then click the [ OK ] button. F-2-32 3) Click [ Generate Key...

- Page 40 Technology > MEAP > Preparation for Using SMS > Device Settings 2-24 5) Check to see that the generated key appears in [ Registered Key and Certificate ]. 3) Select the generated key, and then click the [ Default Key Settings ] button. F-2-38 4) Check that [ SSL ] is displayed in the [ Key Usage ] entry field.

- Page 41 Technology > MEAP > Preparation for Using SMS > Device Settings 2-25 2) Click [ View certificates ]. 4) [ Certificate Import Wizard ] will appear. Click the [ Next ] button. F-2-42 3) Click the [ Install Certificate... ] button on the [ General ] tab. F-2-44 F-2-43 2-25...

- Page 42 Technology > MEAP > Preparation for Using SMS > Device Settings 2-26 5) In [ Certificate Store ], select the [ Place all certificates in the following store ] option, and 7) You will return to the [ Certificate Store ] dialog. Check that "Trusted Root Certification then click the [ Browse ] button.

-

Page 43: How To Check The Serial Number

Technology > MEAP > Preparation for Using SMS > How to Check the Serial Number 2-27 9) A message will appear to indicate that import has been completed successfully. Click the [ Note: OK ] button. A port number can be any integer from 0 to 65535. To avoid port numbers that are frequently used, do not use any integer from 0 to 1023. -

Page 44: Login To Sms

Technology > MEAP > Login to SMS > Procedure to Log in 2-28 Login to SMS ● Checking from the PC browser The serial number of the device is displayed on the SMS login screen, SMS screen, and ■ Procedure to Log in remote UI portal screen. - Page 45 Technology > MEAP > Login to SMS > Procedure to Log in 2-29 ● When SMS Cannot Be Accessed Note: If you forgot the password (SMS login password initialization) SMS Access can be gained also from Remote UI. Access Remote UI and click on SMS shortcut shown on the lower right of the screen to After changing the default SMS login password, if you forgot the new password and cannot gain access to SMS.

- Page 46 Technology > MEAP > Login to SMS > Procedure to Log in 2-30 ● If [ Key and Certificate Settings ] is not set Note: If [ Key and Certificate Settings ] is not set correctly, you cannot access the URL for SMS •...

-

Page 47: Installing An Meap Application

Technology > MEAP > Installing an MEAP Application > Procedure to install applications 2-31 Installing an MEAP Application ■ Procedure to install applications 1) Long on to SMS. ■ Outline 2) Click [ Install MEAP Application ] on the menu. From the MEAP application installation screen, you can install the MEAP application as well as the license file. - Page 48 Technology > MEAP > Installing an MEAP Application > Procedure to install applications 2-32 8) Upon installation completed, click [ To MEAP Application Management ] button shown on CAUTION: the screen to view MEAP Application Management page. • You cannot install only the license. •...

-

Page 49: Resource Information

Technology > MEAP > Resource Information > About MEAP Application Management Page 2-33 Resource Information Note: There are two ways to install an MEAP application. You can install using SMS, or install ■ About MEAP Application Management Page using the [Register/Update Software] screen of the remote UI. Screen example Application Management page shows [ resource information ] for information of the whole device resources including Amount Used, Remaining, and Percent Used. -

Page 50: Meap Specifications

Meanwhile, MEAP Specifications shows other information than defined by Device http://www.canon.com/lms/license/ Specification ID above, including network and security. Thus each model does not always have the same version. - Page 51 Technology > MEAP > MEAP Specifications > What is MEAP Specifications (MEAP Spec Version)? 2-35 MEAP Specifications for each model Description Reserved Product Name Initial MEAP SpecVer iR / iR ADVANCE Series Remote Address Book Supported, RemoteFAX Supported. i-SENSYS LBP7680Cx/ imageCLASS 15, 19, 25, 26, 27, 29, 34, 39, 45, 47, 50, 51, Addition of API that allows acquisition of the HID installation status LBP7680Cdn...

-

Page 52: Meap Application Management

Technology > MEAP > MEAP Application Management > Starting, Stopping, or Uninstalling the MEAP Application 2-36 MEAP Application Management 4) Check to see that the status of the MEAP application in question is either [ Started ] or [ Stopped ]. ■... - Page 53 Technology > MEAP > MEAP Application Management > Starting, Stopping, or Uninstalling the MEAP Application 2-37 ● Procedure to uninstall the MEAP application 1) Log in to SMS to click [ MEAP Application Management ] on the menu. 2) Check that the status of the application you want to uninstall is [ Stop ] and the license has Before uninstalling the MEAP application, check that the following conditions are met.

-

Page 54: Managing The License File

Technology > MEAP > MEAP Application Management > Managing the License File 2-38 ■ Managing the License File ● Procedure adding a license file 1) Log on to SMS. ● Outline 2) On MEAP Application Management, click the name of the application to which you want to The license file management functions allow you to perform the following operations related add a license file. - Page 55 Technology > MEAP > MEAP Application Management > Managing the License File 2-39 4) Click [ Browse ] button, and select the license file you want to install. ● Procedure disabling a license file (suspending a license) CAUTION: • Since the license file cannot be disabled when the application is still running, the application needs to be stopped before disabling the license file.

- Page 56 Technology > MEAP > MEAP Application Management > Managing the License File 2-40 2) Click the name of the application that you want to disable. 4) License Management page appears. Click [ Disable ] button. F-2-79 3) On Application/ License Information page, click [ License Management ] button. F-2-81 5) Click [ Yes ].

- Page 57 Technology > MEAP > MEAP Application Management > Managing the License File 2-41 ● Procedure downloading / removing an invalidated license file 5) License Management page appears. To download, click [ Download ] button. Note: The downloaded license file can be used for reinstallation only in the same iR device (with the same device serial number).

-

Page 58: Other License File Management Functions

Technology > MEAP > MEAP Application Management > Other License File Management Functions 2-42 7) To delete, click [ Delete ] button. ■ Other License File Management Functions ● Reusable license When reinstalling, Disable License file should be downloaded (see “Disabling a License File .”... - Page 59 Technology > MEAP > MEAP Application Management > Other License File Management Functions 2-43 ● License for forwarding 3) Specify the application to be forwarded. If the machine needs to be replaced due to a device failure, you can transfer the license information used in the MEAP application to the new machine and continue its usage.

- Page 60 Technology > MEAP > MEAP Application Management > Other License File Management Functions 2-44 5) The window to confirm whether to create a transfer licence will be displayed. Click [ Yes ]. 8) Specify the download destination, click [ Save ]. F-2-95 9) After downloading the license file for forwarding, click [ Delete ] to display the confirmation screen and click [ Yes ] to delete the file (in consideration of breakage of license for...

-

Page 61: Enhanced System Application Management

Technology > MEAP > Enhanced System Application Management > Procedure Changing Login Services 2-45 Enhanced System Application Management ■ About Login Service The login service is started up to authenticate the user when MEAP-enabled iR device is ■ Outline booted up. Login service changes and install/ uninstall are carried out from the 'System [ Enhanced System Application Management ] mainly manages the login services for logging Management' page. -

Page 62: Procedure Installing Login Services

Technology > MEAP > Enhanced System Application Management > Procedure Installing Login Services 2-46 2) Click the [ SWITCH ] button of the login service you want to switch to. ■ Procedure Installing Login Services Use the following procedure to install the login services. 1) Access SMS, and then click [ System Management ] >... -

Page 63: Procedure Uninstalling Login Services

Technology > MEAP > System Application Management > Procedure to manage System Application 2-47 System Application Management ■ Procedure Uninstalling Login Services Use the following procedure to uninstall the login services. This function manages the login services for logging in to SMS. Also, note that the services need to be stopped ("Installed"... -

Page 64: System Information

Technology > MEAP > System Information > Display of System Information Details 2-48 System Information ■ Display of System Information Details The system information details can be displayed to check more than one pieces of information ■ Outline all at the same time: platform information, system application information, information on the You can check the device's platform information and the MEAP application's system installed MEAP applications, etc. -

Page 65: Printing The System Information Of A Meap Application

Application Name: C-Cabinet Gateway for MEAP Application ID/System Application Name: 03a46668-63e4-4636-9cbb-492b6cef05d5 Application Version: 1.0.0 Status: Resolved Installed on: Tue Oct 21 14:00:11 GMT+09:00 2003 Vendor : Canon Inc. License Status : Installed Maximum Memory Usage : 1024 Registered Service : Item... -

Page 66: Meap Application Information

Technology > MEAP > MEAP Application Information > Procedure to Check MEAP Application Information 2-50 MEAP Application Information 3) The MEAP application information screen appears. ■ Outline You can use this function to check the MEAP application installed on the device. The following information can be checked on the MEAP application information screen. -

Page 67: Check License

Technology > MEAP > Changing SMS Login Password > Procedure to Change the SMS Login Password 2-51 Check License Changing SMS Login Password ■ Outline ■ Outline You can use this function to check the contents of the license file. You can change the password for logging in to SMS. -

Page 68: Meap Application Setting Information Management And Log Management

Technology > MEAP > MEAP Application Setting Information Management and Log Management > Advantages Obtained When Using the Services 2-52 MEAP Application Setting Information Management ■ Advantages Obtained When Using the Services and Log Management By using MEAP Application Configuration Service and MEAP Application Log Service, as long as the MEAP application supports these services, you can perform data management tasks ■... -

Page 69: Meap Application Log Management

Technology > MEAP > MEAP Application Setting Information Management and Log Management > MEAP Application Log Management 2-53 ■ MEAP Application Setting Information Management ■ MEAP Application Log Management The setting data (stored on the device) of the MEAP application which supports the The log data (stored on the device) of the MEAP application which supports the Log Service Configuration Service can be deleted. -

Page 70: Maintenance

Technology > MEAP > Maintenance > When Replacing the PCB 2-54 Maintenance 5) To delete the log The confirmation screen will appear to prompt you to delete the log. Click the [ Yes ] button ■ When Replacing the PCB to delete the log. -

Page 71: Actions To Be Taken When E616 Is Displayed

Technology > MEAP > Maintenance > Actions to be taken when E616 is displayed. 2-55 ● Procedure for reinstalling MEAP applications after replacing the PCB ■ Actions to be taken when E616 is displayed. The following shows the procedure when replacing the PCB. ●... -

Page 72: Meap Safe Mode

Technology > MEAP > Maintenance > MEAP Safe Mode 2-56 ■ MEAP Safe Mode ● How to cancel MEAP SAFE mode If you want to cancel MEAP SAFE mode, just restart the device as usual. It will start in normal ●... -

Page 73: Using Usb Devices

Technology > MEAP > Maintenance > Using USB Devices 2-57 ■ Using USB Devices USB Storage Device Application that supports mass storage MEAP application that Settings: [ MEAP Driver ] device supports system driver ● USB Driver Can use USB mass storage device. Can Cannot use USB mass * MEAP driver (compatibility work only on the applications that support... -

Page 74: Reference Material

(Esplet Type show user interfaces either on Local UI or Web. Esplet is a coined word USB Setting Application) created by Canon, consisting of [ Espresso ] or Italian coffee and [ let ] Registration System driver System driver Application with... - Page 75 Technology > MEAP > Reference material > Glossary 2-59 Terms & Acronyms Definitions and Explanations Terms & Acronyms Definitions and Explanations J2RE A set of basic programs to run applications developed in the programming MEAP Specifications MEAP Spec Version, the term used for the SDK. The version number that (Java 2 Runtime language of Java2.

- Page 76 Technology > MEAP > Reference material > Glossary 2-60 Terms & Acronyms Definitions and Explanations The kit containing information and tools required for software development. (Software Development Kit) Service A functional unit or an application program working on MEAP platform. [ Applications ] are generally termed [ Services ] in Java world.

-

Page 77: Embedded Rds

Technology > Embedded RDS > Product Overview > Features and benefits 2-61 Embedded RDS ■ Features and benefits E-RDS embedded with a network module in advance can realize a front-end processing Product Overview of e-Maintenance/ imageWARE Remote system without attaching any extra hardware equipment. -

Page 78: Service Cautions

Technology > Embedded RDS > E-RDS Setup > Confirmation and preparation in advance 2-62 Service cautions E-RDS Setup ■ Confirmation and preparation in advance 1) After performing the following service actions, it is necessary to perform initializing E-RDS settings (CLEAR), E-RDS settings (E-RDS SWITCH : ON) and communication test (COM- To monitor a device with e-Maintenance/ imageWARE Remote, the following settings are TEST). -

Page 79: E-Rds Setting Items (Service Mode)

Technology > Embedded RDS > E-RDS Setup > Steps to E-RDS settings 2-63 (3) Network settings ■ Steps to E-RDS settings Based on the results of the information obtained in (2) Advance preparations, make the 1. Start [Service Mode]. device network related settings. 2. - Page 80 Technology > Embedded RDS > E-RDS Setup > Steps to E-RDS settings 2-64 5. Perform installation or deletion of the CA certificate if necessary, and reboot the device. 8. Select [On] and press [OK] button. • Installation of the CA certificate: Perform installation from SST. NOTE: •...

-

Page 81: Initializing E-Rds Settings

Technology > Embedded RDS > E-RDS Setup > Initializing E-RDS settings 2-65 If the communication is successful, “Done.” is displayed. If “Could not execute.” (failed) ● Initialization procedure appears, refer to the “Troubleshooting“ and repeat until “Done.” is displayed. 1. Start [Service Mode]. 2. -

Page 82: Faq

Technology > Embedded RDS > FAQ 2-66 No.4 Q: How many log-data can be stored? No.1 A: Up to 5 log data can be saved. The data size of error information is maximum 128 Q: In what case does a communication test with UGW fail? characters. -

Page 83: Troubleshooting

Technology > Embedded RDS > Troubleshooting 2-67 Troubleshooting Remedy 2: Troubleshooting using communication log (COM-LOG) 1) Start [Service Mode]. No.1 2) Select [NETWORK GR.] > [E-RDS] > [COM-LOG] and press [OK] or [ ] button to display Symptom: A communication test (COM-TEST) has failed. List Communication Log screen. - Page 84 Technology > Embedded RDS > Troubleshooting 2-68 No.4 NOTE: Symptom: There was a log, indicating "Device is not ready, try later" in error details of COM- • The detailed error information will be displayed in multiple screens as shown below. Use LOG list.

-

Page 85: Error Code And Strings

Technology > Embedded RDS > Error code and strings 2-69 Error code and strings Code Error strings Cause Remedy 8xxx 0101 Server response Communication with UGW has Perform and complete a error (NULL) been successful, but an error of communication test (COM- The following error information is output in the communication error log details display screen. - Page 86 Technology > Embedded RDS > Error code and strings 2-70 Code Error strings Cause Remedy Code Error strings Cause Remedy 19 8xxx 2004 Server response Communication with UGW has Try again after a period of time. 28 8xxx 2047 Server response Due to network congestion, etc., If this error occurs when the error...

-

Page 87: Disassembly/Assembly

Disassembly/ Assembly ■ List Of Parts ■ External Cover, Internal Cover ■ Controller System ■ Laser Exposure System ■ Image Forming System ■ Fixing System ■ Paper Pickup/Transport/ Output System Disassembly/Assembly... -

Page 88: External View

Disassembly/Assembly > List Of Parts > External View Preface List Of Parts ● Outline External View This chapter describes disassembly and reassembly procedures of the printer. Note the following precautions when working on the printer. 1. CAUTION: Before disassembling or reassembling the printer, be sure to disconnect its power cord from the electrical outlet 2. -

Page 89: List Of Main Unit

Disassembly/Assembly > List Of Parts > List of Main Unit List of Main Unit [12] [13] Name Reference [1] Fixing Unit (Refer to page 3-27) [2] Laser Scanner Unit (Refer to page 3-24) [3] Registration Unit (Refer to page 3-25) [4] Multi-purpose Separation Pad (Refer to page 3-31) [5] Multi-purpose Pickup Roller... -

Page 90: Motor

Disassembly/Assembly > List Of Parts > Motor Motor F-3-2 Name Reference [1] Main Motor (Refer to page 3-19) [2] Duplex Reversal Solenoid (Refer to page 3-23) F-3-3 [3] Main Fan (Refer to page 3-19) [4] Cassette Pickup Solenoid (Refer to page 3-22) Name Main Units Reference... -

Page 91: Solenoid

Disassembly/Assembly > List Of Parts > Heater / Thermo Switch / Thermistor / Switch Solenoid Heater / Thermo Switch / Thermistor / Switch SW1001 SW301 F-3-5 F-3-4 Name Main Units Reference Name Main Units Reference Fixing Heater Fixing Unit Multi-purpose Solenoid (Refer to page 3-22) Fixing Thermo Switch Fixing Unit... -

Page 92: Sensor

Disassembly/Assembly > List Of Parts > PCB Sensor PS918 Control panel PCB PS917 PS922 Connecting PCB PS912 PS916 Laser driver PCB All-night power PCB SW1001 PS914 SW301 Main Controller PCB Power Supply PCB PS915 Sleep Interface PCB F-3-6 Name Main Units Reference PS912 Top Sensor... -

Page 93: Connector Layout Drawing

Disassembly/Assembly > Connector Layout Drawing > Connector List > Internal Connector Layout Drawing ■ Internal J202 Connector List J102 J102 ■ Main Controller PCB J206 J301 J120 J210 J128 J130 J206 J210 J300 J303 ■ Engin Controller PCB J205 J204 J203 J206 J581 J211 J207 J202... - Page 94 Disassembly/Assembly > Connector Layout Drawing > Connector List > Internal J1101 J1101 J1103 J1103 J802 J802 J1101 J1101 J1105 J1105 J801 J801 J1104 J1104 J207 J207 J207 J207 J1105 J1105 J581 J581 J581 J581 J300 J300 J1104 J1104 J301 J301 J251 J251 J300...

-

Page 95: External Cover, Internal Cover

Disassembly/Assembly > External Cover, Internal Cover > Removing the Right Cover External Cover, Internal Cover Removing the Right Cover 1) Remove Cassette [1]. Removing the Left Cover 2) Press Release Button [2] and open Cartridge Door Unit [3]. 1) Remove Cassette [1]. 2) Press Release Button [2] and open Cartridge Door Unit [3]. -

Page 96: Removing The Rear Cover Unit / Duplex Feed Unit

Disassembly/Assembly > External Cover, Internal Cover > Removing the Rear Cover Unit / Duplex Feed Unit 3-10 Removing the Rear Cover Unit / Duplex Feed Unit 4) Remove Rear Cover Unit [1] together with Duplex Feed Unit [2]. • 2 Boss [3] Preparations 1) Remove Right Cover.(Refer to page 3-9) 2) Remove Left Cover.(Refer to page 3-9) -

Page 97: Removing The Upper Cover Unit

Disassembly/Assembly > External Cover, Internal Cover > Removing the Cartridge Cover Unit 3-11 Removing the Upper Cover Unit Removing the Cartridge Cover Unit Preparations Preparations 1) Remove Right Cover.(Refer to page 3-9) 1) Remove Right Cover.(Refer to page 3-9) 2) Remove Left Cover.(Refer to page 3-9) 2) Remove Left Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) Procedure... -

Page 98: Controller System

Disassembly/Assembly > Controller System > Removing the Main Controller Board > Removing the Main Controller Board 3-12 Controller System ■ Removing the Main Controller Board Preparations Removing the Main Controller Board 1) Remove Left Cover.(Refer to page 3-9) Procedure (LBP6680) ■... -

Page 99: Actions Before Replacement (Lbp6670 Only)

Disassembly/Assembly > Controller System > Removing the Main Controller Board > Actions before Replacement (LBP6670 only) 3-13 Procedure (LBP6670) ■ Actions before Replacement (LBP6670 only) 1) Remove Controller Cover [1]. 1) Turn ON the power, and Operate according to the instruction on the screen since the initial •... -

Page 100: Remove The Sleep Interface Pcb

Disassembly/Assembly > Controller System > Remove the Duplex Reverse Sensor Unit 3-14 Remove the Sleep Interface PCB Remove the Duplex Reverse Sensor Unit Preparations Preparations 1) Remove Left Cover.(Refer to page 3-9) 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) Procedure 3) Remove Rear Cover Unit.(Refer to page 3-10) 1) Remove Power Supply PCB [1]. -

Page 101: Remove The All-Night Power Supply Pcb

Disassembly/Assembly > Controller System > Remove the Power Supply PCB 3-15 Remove the All-Night Power Supply PCB Remove the Power Supply PCB Preparations Preparations 1) Remove Right Cover.(Refer to page 3-9) 1) Remove Right Cover.(Refer to page 3-9) Procedure Procedure 1) Remove All-Night Power Supply PCB [1]. -

Page 102: Removing The Engine Controller Board

Disassembly/Assembly > Controller System > Removing the Engine Controller Board 3-16 Removing the Engine Controller Board 3) Remove 7 connectors [1] and Terminal [2]. Preparations 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) Procedure 1) Remove 6 connectors [3] from harness guide [2]. - Page 103 Disassembly/Assembly > Controller System > Removing the Engine Controller Board 3-17 5) Disconnect flat cable [1]. 8) Disengage 2 latch [1] on left and right side of frame, and move Engine Controller Board [2] 6) Disengage harness [3] from 3 harness guide [2]. downwards.

-

Page 104: Removing The Control Panel Unit

Disassembly/Assembly > Controller System > Removing the Control Panel Unit 3-18 Removing the Control Panel Unit 9) Pull 1 harness [1] and 1 flat cable [2] out towards the inside. 10) Remove Engine Controller Board [3]. Preparations 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) 4) Remove Upper Cover Unit.(Refer to page 3-11) -

Page 105: Removing The Main Motor

Disassembly/Assembly > Controller System > Removing the Main Fan 3-19 Removing the Main Motor Removing the Main Fan Preparations Preparations 1) Remove Left Cover.(Refer to page 3-9) 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) 3) Remove Rear Cover Unit.(Refer to page 3-10) -

Page 106: Removing The Main Drive Unit

Disassembly/Assembly > Controller System > Removing the Main Drive Unit 3-20 Removing the Main Drive Unit 2) Remove harnesses from the guide [3]. • 3 Connectors [1] Preparations • 1 Wire Saddle [2] 1) Remove Left Cover.(Refer to page 3-9) 3) Remove main switch unit [4]. -

Page 107: Removing The Duplex Drive Unit

Disassembly/Assembly > Controller System > Removing the Duplex Drive Unit 3-21 Removing the Duplex Drive Unit 6) Remove Platei [1]. • 2 Screws [2] Preparations 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) 4) Remove Main Fan Unit.(Refer to page 3-11) Procedure 1) Remove Duplex Drive Unit [1]. -

Page 108: Removing The Cassette Pickup Solenoid

Disassembly/Assembly > Controller System > Removing the Multi-purpose Solenoid 3-22 Removing the Cassette Pickup Solenoid Removing the Multi-purpose Solenoid Preparations Preparations 1) Remove Right Cover.(Refer to page 3-9) 1) Remove Left Cover.(Refer to page 3-9) Procedure Procedure 1) Remove main switch unit [1]. 1) Remove Multi-purpose Solenoid [1]. -

Page 109: Removing The Duplex Reversal Solenoid

Disassembly/Assembly > Controller System > Removing the Duplex Reversal Solenoid 3-23 Removing the Duplex Reversal Solenoid Preparations 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) 4) Remove Main Fan.(Refer to page 3-19) 5) Remove Duplex Drive Unit.(Refer to page 3-21) Procedure 1) Remove Duplex Reversal Solenoid [1]. -

Page 110: Laser Exposure System

Disassembly/Assembly > Laser Exposure System > Removing the Laser Scanner Unit 3-24 Laser Exposure System CAUTION: Do not disassemble the laser scanner unit at a field. Removing the Laser Scanner Unit It may cause a malfunction. Preparations 1) Remove Right Cover.(Refer to page 3-9) 2) Remove Left Cover.(Refer to page 3-9) 3) Remove Rear Cover Unit.(Refer to page 3-10) 4) Remove Upper Cover Unit.(Refer to page 3-11) -

Page 111: Image Forming System

Disassembly/Assembly > Image Forming System > Removing the Registration Unit 3-25 Image Forming System Removing the Registration Unit Preparations Removing the Transfer Roller 1) Remove Left Cover.(Refer to page 3-9) 2)Remove Right Cover.(Refer to page 3-9) Procedure 3) Remove Rear Cover Unit.(Refer to page 3-10) 4) Remove Upper Cover Unit.(Refer to page 3-11) CAUTION: When assembling / disassembling the transfer charging roller, hold the shaft or bushing... - Page 112 Disassembly/Assembly > Image Forming System > Removing the Registration Unit 3-26 3) Remove gear cover [3] and Registration Unit [1]. • 5 Screw [2] F-3-47 3-26 Disassembly/Assembly > Image Forming System > Removing the Registration Unit...

-

Page 113: Fixing System

Disassembly/Assembly > Fixing System > Removing the Fixing Unit 3-27 Fixing System Points to Note at Installation: Fit the Protrusion [2] of the Gear [1] With the Cut-off of the Gear [3] and Install it. Removing the Fixing Unit Fit the Cut-off [4] of the Gear [1] With the Teeth of the Fan Gear [5] and Install it. Preparations 1) Remove Left Cover.(Refer to page 3-9) 2) Remove Right Cover.(Refer to page 3-9) - Page 114 Disassembly/Assembly > Fixing System > Removing the Fixing Unit 3-28 2) Remove transport guide [1]. 4) Remove Fixing Unit [1]. • 2 harness guide [2] • 3 Connectors [2] • 5 Connector [3] • 1 Terminal [3] • 2 Screws [4] F-3-50 3) Remove Feed guide [1].

-

Page 115: Paper Pickup/Transport/Output System

Disassembly/Assembly > Paper Pickup/Transport/Output System > Removing the Cassette Pickup Roller 3-29 Paper Pickup/Transport/Output System 3) Rotate left-side bushing [1] in arrow direction. • 1 Tab [2] Removing the Cassette Pickup Roller CAUTION: Do not touch the surface of the Cassette Pickup Roller when removing or mounting it. 1) Remove Cassette. -

Page 116: Removing The Cassette Separation Pad

Disassembly/Assembly > Paper Pickup/Transport/Output System > Removing the Multi-purpose Pickup Roller 3-30 Removing the Cassette Separation Pad Removing the Multi-purpose Pickup Roller CAUTION: CAUTION: Do not touch the surface of the Cassette Separation Pad when removing or mounting it. Do not touch the surface of the Multi-purpose Pickup Roller when removing or mounting 1) Remove Cassette. -

Page 117: Removing The Multi-Purpose Separation Pad

Disassembly/Assembly > Paper Pickup/Transport/Output System > Removing the Multi-purpose Separation Pad 3-31 Removing the Multi-purpose Separation Pad Preparation 1) Removing the Multi-purpose Pickup Roller.(Refer to page 3-30) Procedure CAUTION: Do not touch the surface of the Multi-purpose Separation Pad when removing or mounting it. -

Page 118: Maintenance And Inspection

Maintenance and Inspection ■ Periodically Replaced Parts ■ Consumable Parts ■ Periodical Service ■ Cleaning Maintenance and Inspection... -

Page 119: Periodically Replaced Parts

Maintenance and Inspection > Cleaning > Cleaning at Service Visit Periodically Replaced Parts Periodically Replaced Parts • Periodic replacement parts are not required in this printer. Consumable Parts Durables Replaced by the Service Person • Consumable parts are not required in this printer. Periodical Service Periodical Service •... -

Page 120: Trouble Shooting

Trouble Shooting ■ Trouble Shooting ■ Error Codes ■ Service Mode ■ Version Upgrade ■ Updater ■ Debug log ■ Backup/Restoration by Expansion ROM for servicing and Sublog Board Trouble Shooting... -

Page 121: Engine-Test Page

Trouble Shooting > Trouble Shooting > Test Pages > Controller-Test page Trouble Shooting ■ Controller-Test page The data for test charts are created in the main controller. If no problem is found on the output Test Pages test charts, the cause may lie in the PDL input or the reader. Printing test pages helps determine if the printer is functioning. -

Page 122: Device Log List

Trouble Shooting > Trouble Shooting > Adjustment of Fixing System > Nip-width specifications Device Log List Adjustment of Fixing System Print jam and error logs. ■ Nip-width specifications NOTE: Method to display the test print The nip-width of the fixing unit is not adjustable in this printer, however the improper nip-width It appears in the menu by pressing [Status Monitor/Cancel key] + [Utility] may cause the poor fixing. -

Page 123: Error Codes

Trouble Shooting > Error Codes > Error Code Details Error Codes Detail Item Description Code Code E06F 0068 Title EEPROM communication error Error Code Details Detection description EEPROM communication error Remedy 1. Reconnect the connector on the Engine Contoroller PCB. 2. - Page 124 Trouble Shooting > Error Codes > Error Code Details Detail Item Description Detail Item Description Code Code Code Code E602 0009 Title MEAP cannot be started. E602 1313 Title Device access error Detection description MEAP cannot be started due to an error caused by invalid power Detection description Device access error down.

- Page 125 Trouble Shooting > Error Codes > Error Code Details Detail Item Description Detail Item Description Code Code Code Code E730 100A Title System error E744 1000 Title Firmware error Detection description System error Detection description Mismatch of the model for which the firmware was downloaded is detected.

-

Page 126: Jam Codes

Trouble Shooting > Error Codes > Jam Codes Jam Codes Jam Code Cause Jam Position High Order Low Order Paper feed delay jam 1 – Paper feed retention jam 1 – Fixing output delay jam 1 – Fixing output retention jam 1 – Internal paper jam 1 –... -

Page 127: Service Mode

Trouble Shooting > Service Mode Service Mode Item Description USB-H To set to enable/disable the USB host function. By turning ON the host function, USB memory can be used. ■ ADJUST GR. (Note) Points to note when pulling out the USB memory Item Description Setting Range... -

Page 128: Log Gr

Trouble Shooting > Service Mode ■ F/W UPDATE GR. Item Description SN-MAIN To display or overwrite serial numbers. Item Description (LBP6670dn A serial number is described as “XXXXYYYY”; the “XXXX” part consists of alphabets (A To upgrade all firmware using the USB. only) to Z) while the “YYYY”... - Page 129 Trouble Shooting > Service Mode 5-10 Item Description Item Description E-RDS E-RDS ON: Use Embedded-RDS. SLEEP ADVERTISE SWITCH To set whether to use the sleep notification. SWITCH OFF: Do not use Embedded-RDS. ON: Notify sleep. OFF: Do not notify sleep. RGW- To check and set the server URL.

-

Page 130: Sp.admin.mode

Trouble Shooting > Service Mode 5-11 Item Description PFW SETTING ILOGKEEP The time is saved when an address is blocked by packet filtering. The log is not notified to UI when an access is made from the same address within the specified period of time. The specified period of time mentioned above can be set. -

Page 131: Version Upgrade

Trouble Shooting > Version Upgrade > Overview > Checking the Version 5-12 Version Upgrade ■ Checking the Version In order to check the model name and the version, it is necessary to output a status print. Overview 1) Utility Menu > Configuration Page ■... -

Page 132: Version Upgrade Using Ust

Trouble Shooting > Version Upgrade > Version Upgrade Using UST > Preparation 5-13 Version Upgrade Using UST ■ Preparation Necessary System Environment • OS (Any of the following) • Microsoft Windows 2000 Server/Professional Edition • Microsoft Windows XP Professional/Home Edition* •... -

Page 133: Downloading The Firmware

Trouble Shooting > Version Upgrade > Version Upgrade Using UST > Downloading the Firmware 5-14 ■ Downloading the Firmware 4) A reset starts and [UPDATEMODE READY] is displayed. 1) Select Setup > User Maintenance > Update Firmware UPDATEMODE READY User Maintenance Substitute Size Special Print Mode A Special Print Mode... - Page 134 Trouble Shooting > Version Upgrade > Version Upgrade Using UST > Downloading the Firmware 5-15 7) Click the "Next" button. 9) Click the "Start" button. F-5-12 F-5-14 8) Select the USB connection device, and click the "Next" button. 10) When the warning screen is displayed, click the "Yes" button. F-5-15 F-5-13 5-15...

- Page 135 Trouble Shooting > Version Upgrade > Version Upgrade Using UST > Downloading the Firmware 5-16 Then start downloading. F-5-16 Note: "DOWNLOADING XX%" and "UPDATING XX%" are displayed in the display of the host machine during downloading. (XX shows the progress degree.) 11) When downloading is completed, click the "OK"...

-

Page 136: Updater

Updater function enables users to distribute firmware through CDS via Internet. Particularly information to CDS. e-RDS on e-Maintenance/UGW (called NETEYE in Japan)-enabled devices, firmware can be 4) Download firmware Canon Inc. updated remotely, which effectively slashes costs incurred in field services. Firmware Upload Updater Firmware • MEAP Application... -

Page 137: System Configuration

Firmware firmware Group Firmware Updating downloaded firmware Cancelling downloaded Service Command for Firmware Distribution firmware Technician Canon Inc. Acquiring firmware distribution information registered from F-5-20 Notifying firmware version information Periodical update Inquiring license for MEAP application option MEAP application/ system option... -

Page 138: Distribution Flow

Trouble Shooting > Updater > Overview > Distribution Flow 5-19 ■ Distribution Flow MEAP Application Installation Flow MEAP application installation method using service mode is not provided. Firmware Installation Flow Be sure to use the user mode to install. Service technicians provide firmware install services in the following 4 methods. : Operator of each company : User operation a: UGW-linked download and update... -

Page 139: Limitations And Cautions

Trouble Shooting > Updater > Overview > Limitations and Cautions 5-20 ■ Limitations and Cautions Job/Function Receiving Printing Queued print type jobs ● Limitations PRINT Wait for EOJ Wait for EOJ Wait for EOJ (end of job) Changing Date/Time on Device I-FAX Receipt Cancel Wait for EOJ... -

Page 140: Preparation

Trouble Shooting > Updater > Overview > Preparation 5-21 ■ Preparation ● Setting Sales Company’s HQ When using devices input in the markets listed below, the default setting of Sales Company’s ● Overview of Preparation HQ should be changed before obtaining firmware distributed from CDS. Unless the setting is The following should be prepared before using Updater. - Page 141 Trouble Shooting > Updater > Overview > Preparation 5-22 ● Network Settings 2. Type the password [*28*] then log in it. Connecting to External Network Caution: The method of connecting to external network is similar to a normal network connection In the case of the following, you cannot log in even if you input a right password.

- Page 142 Trouble Shooting > Updater > Overview > Preparation 5-23 Communication Test Caution: This section describes how to check if the communication is normally done to the distribution The setting change of the output level influences a performance. server and/or the file server. Refer to System Management Operations>...

- Page 143 Trouble Shooting > Updater > Overview > Preparation 5-24 3. The Communication Test is carried out. ● Enabling UGW Link When installing the firmware in the method of “UGW-linked Download and Update” or “UGW- linked Download”, the following should be set before actually using UGW link. SERVICE MODE >FUNCTION GR.

- Page 144 Trouble Shooting > Updater > Overview > Preparation 5-25 ● Enabling [Install Application/Options] Button of User Mode (Remote ● Enabling [Manual Update] Button of User Mode (Remote UI) To allow users to install firmware from Updater using the file on Local PCs, the setting of firmware installation should be set to ON for users in advance.

- Page 145 Trouble Shooting > Updater > Overview > Preparation 5-26 ● Enabling [Scheduled Update] Button of User Mode Service Setting of Device Service Mode SERVICE MODE >FUNCTION GR. >MEAP Technician >CDS-LVUP (On -> Off) • Remote UI screen of Updater when the setting is not enabled (CDS-LVUP (Off)): F-5-34 •...

-

Page 146: System Management Operations

Trouble Shooting > Updater > Overview > System Management Operations 5-27 ■ System Management Operations Log Output Log Level Trace Information Important Message Ordinary Error System Error ● Various Setting Setting Log Level This section describes how to set system log levels. 1. - Page 147 Trouble Shooting > Updater > Overview > System Management Operations 5-28 ● Displaying Logs 3. Press [Switch] button. Update Logs This section describes how to confirm System Option/MEAP Application Installation Logs and Firmware Update Logs. 1. Select [Settings/Registration] > [License/Other] > [Register/Update Software] > [Display Logs/Communication Test] from management mode of Remote UI.

- Page 148 Trouble Shooting > Updater > Overview > System Management Operations 5-29 System Logs 3. Press [Switch] button. This section describes how to confirm System Logs. 4.Updater internal logs are displayed. 1. Select [Settings/Registration] > [License/Other] > [Register/Update Software] > [Display Logs/Communication Test] from management mode of Remote UI.

-

Page 149: Ugw-Linked Download And Update (Full-Remote Update)

Trouble Shooting > Updater > Overview > b. UGW-linked Download (Remote Distribution Update) 5-30 ■ a. UGW-linked Download and Update (Full-remote Update) ■ b. UGW-linked Download (Remote Distribution Update) See the figure below for the operational flow of “UGW-linked Download and Update”. See the figure below for the operational flow of “UGW-linked download”. -

Page 150: Deleting The Scheduled Firmware Delivery

Trouble Shooting > Updater > Overview > Updating the Downloaded Firmware (Application of Firmware) 5-31 3) Press the [Yes] button in response to the confirmation to execute the operation. 4) As the deletion result is displayed, check that it has been deleted, and then press the [OK] button. -

Page 151: Deleting The Downloaded Firmware

Trouble Shooting > Updater > Overview > Deleting the Downloaded Firmware 5-32 ■ Deleting the Downloaded Firmware Here is explained the method to delete the firmware downloaded by the Updater. 1) From the administrator mode of the remote UI, select [Settings/Registration] > [License/ Other] >... -

Page 152: Maintenance

Trouble Shooting > Updater > Overview > Maintenance 5-33 ■ Maintenance ● Upgrading Updater The firmware installed in the device should be also upgraded when upgrading Updater. The setting information and logs (update logs/system logs) are inherited in the upgraded version. ●... -

Page 153: Faq

Trouble Shooting > Updater > Overview > FAQ 5-34 ■ FAQ No.3 Q: In the course of “UGW-linked download”, what will happen if the user downloads the ● FAQ on Installing Firmware firmware before the service technician update the firmware downloaded with “UGW-linked No.1 download”... - Page 154 Trouble Shooting > Updater > Overview > FAQ 5-35 No.7 ● FAQ on Installing MEAP Application/System Option Q: Can we cancel the operation during firmware download? No.1 A: Yes. [Cancel] button is shown. Q: What happens if a MEAP application is installed in the system with insufficient storage (You cannot cancel UGW-linked Download.) free space? A: An error message is shown.

- Page 155 Trouble Shooting > Updater > Overview > FAQ 5-36 ● FAQ on General Matters of Updater No.2 Q: How can operations using Updater be masked on the users' side? No.1 A: Be sure to perform the following from the service mode. Q: What preparation is needed in each installation method? •...

-

Page 156: Error Messages

Trouble Shooting > Updater > Overview > Error Messages 5-37 ■ Error Messages Error messages displayed in Remote UI are shown below. As to error codes, see the next list. Messages Timing of display Cause Remedy An error occurred with the delivery In communicating with the System error occurred in server. - Page 157 Trouble Shooting > Updater > Overview > Error Messages 5-38 Messages Timing of display Cause Remedy Delivery Server : Connect Failed Communication test, etc. In the communication test, failed to connect to the Check the network environment of the device, and re-execute the job. File Server : Retrieve Failed (communication test result delivery server.

- Page 158 Trouble Shooting > Updater > Overview > Error Messages 5-39 Messages Timing of display Cause Remedy An error occurred. communication test, etc. The max value (space/file) was exceeded and new Check if the log file exceeded the max value. Error Code: [xxx] (main screen) log was not accepted.

- Page 159 Trouble Shooting > Updater > Overview > Error Messages 5-40 Messages Timing of display Cause Remedy An error occurred. UGW linkage (main UGW linkage was turned ON when eRDS was OFF.For a device using eRDS, turn ON the eRDS. For a device not using eRDS, turn OFF the Error Code: [xxx] screen) UGW linkage.

- Page 160 Trouble Shooting > Updater > Overview > Error Messages 5-41 Messages Timing of display Cause Remedy An error occurred. Check the Update UGW linkage (main eRDS sent an order but Updater failed to connect Conduct a communication test to analyze the cause of the error. After solving the cause, Firmware screen.

- Page 161 Trouble Shooting > Updater > Overview > Error Messages 5-42 Messages Timing of display Cause Remedy Delivery Error UGW linkage (Update eRDS sent an order but Updater failed to connect Conduct a communication test to analyze the cause of the error. After solving the cause, Error Code: [xxx] Firmware screen) to the server.

-

Page 162: Error Codes

Trouble Shooting > Updater > Overview > Error Codes 5-43 ■ Error Codes Error Codes displayed on Remote UI and how to read them. ● How to read an error code 84 0142 06 Code Value Contents The first digit Error Error field The second digit... - Page 163 Trouble Shooting > Updater > Overview > Error Codes 5-44 Error Code (hex number) Description Remedy Cause of error The first The second The 3rd - 4th The 5th digit The 6 - 8th digits CDS file Network digit Error digit digits Method Category...

- Page 164 Trouble Shooting > Updater > Overview > Error Codes 5-45 Error Code (hex number) Description Remedy Cause of error The first The second The 3rd - 4th The 5th digit The 6 - 8th digits CDS file Network digit Error digit digits Method Category...

- Page 165 Trouble Shooting > Updater > Overview > Error Codes 5-46 Error Code (hex number) Description Remedy Cause of error The first The second The 3rd - 4th The 5th digit The 6 - 8th digits CDS file Network digit Error digit digits Method Category...

- Page 166 Trouble Shooting > Updater > Overview > Error Codes 5-47 Error Code (hex number) Description Remedy Cause of error The first The second The 3rd - 4th The 5th digit The 6 - 8th digits CDS file Network digit Error digit digits Method Category...

-

Page 167: Debug Log

• When the error is suspected of links with firmware rather than a mechanical/electrical failure. * Collection of Sublog is not necessary when the reproduction procedure is identified and the error can be reproduced by the sales company HQ or the Canon staff who is in charge of quality follow-up. 5-48... -

Page 168: Collecting Sublog

Trouble Shooting > Debug log > Collecting Sublog > Generating the log 5-49 Collecting Sublog 2) Install the Sublog Expansion Board into the slot over the controller. ■ Flow of collecting Sublog Installing the Sublog Board Install the board to the host machine. Generating the log When the Sublog Board is installed, it records the log all time. -

Page 169: Collecting Log

Trouble Shooting > Debug log > Collecting Sublog > Collecting log 5-50 ■ Collecting log 4) Select [YES]. 1) Connect the PC and the host machine by a network cable and check that communication Execute? is available. a. When directly connecting a PC and the host machine, connect by a cross cable. b. - Page 170 Trouble Shooting > Debug log > Collecting Sublog > Collecting log 5-51 7) Enter the user name [guest] and password [welcome.]. C:╲Users╲1234>ftp 172.16.1.170 Connected to 172.16.1.170. C:╲Users╲1234>ftp 172.16.1.170 220 DRY FTP server ready. Connected to 172.16.1.170. User (172.16.1.170:(none)>:guest 220 DRY FTP server ready. 331 Password required for guest.

- Page 171 Trouble Shooting > Debug log > Collecting Sublog > Collecting log 5-52 (12) Check that the log is stored at the specific location on the PC. Windows (C:) > Users > User name F-5-62 5-52 Trouble Shooting > Debug log > Collecting Sublog > Collecting log...

-

Page 172: Backup/Restoration By Expansion Rom For Servicing And Sublog Board

Trouble Shooting > Backup/Restoration by Expansion ROM for servicing and Sublog Board > Function Overview > Target Data for Backup 5-53 Backup/Restoration by Expansion ROM for servicing ■ Target Data for Backup and Sublog Board LBP7660C User mode setting values Function Overview Service mode setting values Page counter... -

Page 173: Backup And Restoration (Export And Import)

Trouble Shooting > Backup/Restoration by Expansion ROM for servicing and Sublog Board > Backup and Restoration (Export and Import) > Installing the Expansion ROM for servici 5-54 Backup and Restoration (Export and Import) ■ Installing the Expansion ROM for servicing and Sublog Board 1) Install the Expansion ROM for servicing to the Sublog Board. -

Page 174: Backup Procedure (Export)

Trouble Shooting > Backup/Restoration by Expansion ROM for servicing and Sublog Board > Backup and Restoration (Export and Import) > Restoration Procedure (Import) 5-55 ■ Backup Procedure (Export) ■ Restoration Procedure (Import) 1) The menu is displayed when turning ON the power while the Sublog Board attached with 1) Install the unused Main Controller PCB which has been installed with the Sublog Board (to the Expansion ROM for servicing is installed. -

Page 175: Others

Trouble Shooting > Backup/Restoration by Expansion ROM for servicing and Sublog Board > Others > Deletion (Erase) 5-56 Others 3) The data in the Sublog Board is deleted and the following message is displayed in the case of successful completion. ■... -

Page 176: List Of Error Messages

Trouble Shooting > Backup/Restoration by Expansion ROM for servicing and Sublog Board > Others > List of Error Messages 5-57 ■ List of Error Messages The following messages are displayed when certain failures occur during operation. List of Messages Detail Sublog board not found Sublog Board is not installed. -

Page 177: Appendex

Appendex ■ General Timing Chart ■ General Circuit Diagram ■ LIst of Signals... -

Page 178: Service Tools

Appendex > Service Tools > Solvents and Oil List Service Tools Special Tools No special tools are required for servicing this printer other than the standard tools. Solvents and Oil List Type Purpose Remark Lubricant Apply to gear • MOLYKOTE® EM-50L (Dow Corning Corporation) •... -

Page 179: General Timing Chart

Appendex > General Timing Chart General Timing Chart ■ General Timing Chart Timing chart two consecutive prints on LTR paper Power switch ON Operation WAIT STBY INTR PRINT LASTR STBY TOP sensor (PS912) Fixing delivery sensor (PS915) Print start command (EEC12) Scanner Motor Laser Diode BD Output signal (BDO) -

Page 180: General Circuit Diagram

General Circuit Diagram General Circuit Diagram PS914 PS915 PS918 PS912 PS922 INL101 Cassette MP tray J4_PAN PS916 FD tray Media full media presence media presence Fixing Assembly AC-H media full sensor sensor sensor sensor sensor Fixing delivery sensor LCD_PWM All-night AC-N UN22 power PCB... -

Page 181: Backup Data

Backup Data Data to Be Stored Data Replacement Delete User Backup Service Backup Location User function Service function When Initializing Initializing IPSec SD Card (Fixing unit/ FLASH DC Controller E-RDS > Can Data Method Location to Method 1 Location to Method 2 Location to Replacing Controller...