Table of Contents

Advertisement

1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2

Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3

Unpacking Of Idu And Odu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4

Idu Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1

Sfp Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2

Fan Unit Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

5

Odu Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1

Antenna Direct Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.1

Basic Installation for Antenna & ODU . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.2

With Hybrid/Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.1.3

With Tx Span Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.1.4

With Ortho-Mode Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.2

Feeder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5.2.1

For Coaxial Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-45

5.2.2

For Waveguide Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

5.2.3

For Waveguide Connection With Hybrid . . . . . . . . . . . . . . . . . . . . . . . 5-54

5.3

Other Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.3.1

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60

5.3.2

Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

5.4

Hybrid Combiner Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66

6

Cable Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1

5D Coaxial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2

8D Coaxial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.3

Other Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-44

7

Wiring And Forming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8

Frame Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

9

Waterproof Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

10

Antenna Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Installation

Submission Prohibited

NEC Internal Use Only

SECTION I INSTALLATION

- 1 -

iPASOLINK 200

CONTENTS

NWD-107460-02E

November, 2010

Advertisement

Table of Contents

Summary of Contents for NEC iPasolink 200

- Page 1 Submission Prohibited NEC Internal Use Only - 1 - iPASOLINK 200 SECTION I INSTALLATION CONTENTS INSTALLATION ............1-1 PACKAGES .

- Page 2 Submission Prohibited NEC Internal Use Only - 2 - This page is intentionally left blank. NWD-107460-02E Installation...

- Page 3 Submission Prohibited NEC Internal Use Only INSTALLATION 1. INSTALLATION The standard installation is summarized in this section. Included herein is information on typical installation work flow and guides for IDU installation, ODU installation, Antenna (ANT) installation, waveguide connection and coaxial cable connections.

- Page 4 Submission Prohibited NEC Internal Use Only INSTALLATION This page is intentionally left blank. NWD-107460-02E Installation...

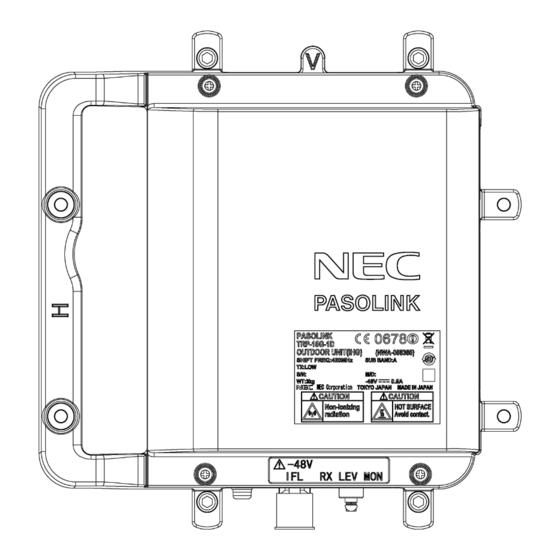

- Page 5 Submission Prohibited NEC Internal Use Only PACKAGES 2. PACKAGES Each unpacked component of the [ ] GHz [ ] MB digital radio system must be checked as shown below. Contens List Drawing No. IDU and ODU Fig. 2-1 Mounting Bracket Fig.

- Page 6 Submission Prohibited NEC Internal Use Only PACKAGES (*1) (6-11 GHz) (13-38 GHz) (Optional slots are mounted.) (Optional slots are blanked.) Description TRP-( )G-1D (ODU) MDP-400MB-1B (IDU) O-Ring (Attached to the waveguide type ODU) Power Connector (Housing (AMP: 1-178288-4 (x1 ea)) or DK-3100S-04R (x1 ea) and...

- Page 7 Submission Prohibited NEC Internal Use Only PACKAGES (Supplied with Antenna) Description Pole Mounting Bracket for Coaxial Cable (6/7/8 GHz)/Waveguide Connection Type Pole Mounting Bracket for Antenna direct Mounting Type Fig. 2-2 Pole Mounting Bracket Installation NWD-107460-02E...

- Page 8 Submission Prohibited NEC Internal Use Only D-Sub Connector AUX-S MDR Connector 16E1-S ODU (13-38 GHz) ODU (6-11 GHz) N-P Connector N-P Connector Lug (FG) Lug (FG) Power Supply Connector STM1-S SFP Module Connector PS-S TNCP Connector D-Sub Connector (Female) Lug (FG)

- Page 9 Submission Prohibited NEC Internal Use Only D-Sub Connector AUX-S MDR Connector 16E1-S ODU (6-11 GHz) ODU (13-38 GHz) N-P Connector Lug (FG) Lug (FG) N-P Connector Power Supply Connector STM1-S SFP Module Connector TNCP Connector PS-S Lug (FG) Modular D-Sub Connector...

- Page 10 Submission Prohibited NEC Internal Use Only PACKAGES This page is intentionally left blank. NWD-107460-02E Installation...

- Page 11 Submission Prohibited NEC Internal Use Only UNPACKING of IDU and ODU 3. UNPACKING of IDU and ODU The unpacking procedures for the IDU and ODU are shown in following chart. IDU: Procedure 3-1 ODU: Procedure 3-2 Note When conveying the IDU or ODU to another place, the original packing should be used to avoid damage.

- Page 12 Submission Prohibited NEC Internal Use Only UNPACKING of IDU and ODU Take out the accessories, IDU wrapped in the poly sheet and cushioning materials (pads), Take out the IDU from the poly sheet. Inspect the IDU. NWD-107460-02E Installation...

- Page 13 Submission Prohibited NEC Internal Use Only UNPACKING of IDU and ODU Procedure 3-2 Unpacking Method for ODU Open the top cover of the packing box. Recycle Mark Care Mark Package Label Recycle Mark Package Label Care Mark Installation NWD-107460-02E...

- Page 14 Submission Prohibited NEC Internal Use Only UNPACKING of IDU and ODU Take out the ODU, cushioning materials (pads) and poly sheet, TOP PAD POLY SHEET BOTTOM PAD INNER PACKING BOX Take out the ODU from the poly sheet. Inspect the ODU.

- Page 15 Submission Prohibited NEC Internal Use Only IDU MOUNTING 4. IDU MOUNTING The installation procedure for the IDU explains in Procedure 4-1. The IDU should be installed in the radio station. Procedure 4-1 Mounting Methods of the IDU The supporting brackets are attached on front position of the IDU.

- Page 16 Submission Prohibited NEC Internal Use Only IDU MOUNTING Fix each side of the IDU to the 19-inch rack with the two screws, To mount the IDU in a 19-inch rack, space for heat dissipation is not required for the top, bottom, and rear of the equipment because built-in forced air cooling fan is provided.

- Page 17 Gigabit Ethernet. The SFP operates with 850 nm laser transmitter and has a duplex LC connector. Electrical SFP The SFP modules also accept LC fiber connectors with Polished Connector (LC-PC) or Ultra Polished Connector (LC-UPC). The SFP modules purchasing from NEC are recommendable to use. Connectors for the SFP module. Installation NWD-107460-02E...

- Page 18 Submission Prohibited NEC Internal Use Only IDU MOUNTING Procedure Install the SFP module by the following steps: Step 1 Step 2 Step 2 NWD-107460-02E Installation...

- Page 19 Submission Prohibited NEC Internal Use Only IDU MOUNTING Step 3 Step 3 Step 4 SFP modules are installed. Note A distinct detent ’click’ will be heard when the SFP is fully and properly inserted. Installation NWD-107460-02E...

- Page 20 When replacing the FAN unit used in the IDU, perform the following procedures. Notes NEC recommends replacement of the FAN unit approximately every three years, even if the FAN unit operates normally. In the case FAN alarm occurred, replace the FAN unit immediately.

- Page 21 Submission Prohibited NEC Internal Use Only IDU MOUNTING Step 2 Step 2 Step 3 Step 3 Step 4 After FAN unit installation. (The state that replaement was completed.) Installation NWD-107460-02E...

- Page 22 Submission Prohibited NEC Internal Use Only IDU MOUNTING 4.3 Fuse Replacement When the power is supplied to the power supply connector but the IDU can not be powered, check the conduction of fuse in the IDU. Disconnect power supply cable from power supply connector.

- Page 23 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5. ODU MOUNTING The procedures for mounting and demounting the ODU are described here. There are two types of mounting for the Antenna Direct Mounting type and Feeder Connecting type. The ODU should be installed in the radio station.

- Page 24 Submission Prohibited NEC Internal Use Only ODU MOUNTING Position of Large size O-ring Position of Small size O-ring for Waveguide Connection for Antenna Direct Mounting ANDREW Antenna Position of Large size O-ring Position of Small size O-ring for Antenna Direct Mounting...

- Page 25 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5.1 Antenna Direct Mounting 5.1.1 Basic Installation for Antenna & ODU Note The details are referred to the installation manual which is attached to the antenna. Installation of Bracket Install the bracket to the antenna pole,...

- Page 26 Submission Prohibited NEC Internal Use Only ODU MOUNTING RFS SB1 Type Bracket NWD-107460-02E Installation...

- Page 27 Submission Prohibited NEC Internal Use Only ODU MOUNTING Note The values in the following table are valid for screws and bolts which have been greased according to the installation instructions. Torques for RFS Bolt U-Bolt, V-Bolt (Pipe mount & safety collar)

- Page 28 Submission Prohibited NEC Internal Use Only ODU MOUNTING Mount Assembly (RFS C-Mount Type) Pipe diameter: 48-114 mm RFS C-Mount type Bracket NWD-107460-02E Installation...

- Page 29 Submission Prohibited NEC Internal Use Only ODU MOUNTING RFS C-Mount type Bracket Installation NWD-107460-02E...

- Page 30 Submission Prohibited NEC Internal Use Only ODU MOUNTING Fix the ODU to the bracket by tightening the M6 screws (four locations), Notes Being careful, tighten alternately and gradually four screws. Figure shows V polarization. Be careful not to damage the O-ring (Antenna).

- Page 31 Submission Prohibited NEC Internal Use Only ODU MOUNTING Hole for guide pin O-ring RFS SB1 type Bracket ODU (6-11 GHz) ODU (13-38 GHz) Hole for guide pin Note Set the ODU to the bracket after polarization of the ODU is confirmed.

- Page 32 Submission Prohibited NEC Internal Use Only 5-10 ODU MOUNTING Insert guide pin on the hole of bracket to set the position of screws, Guide pin Caution: Align flanges on antenna and ODU correctly, and fix the ODU with four screws.

- Page 33 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-11 Member of tower No.1 ODU Member of tower Pole Pole No.1 ODU Pole 1+0 System ODU (6-11 GHz) Member of tower No.2 ODU No.2 ODU Pole ODU (6-11 GHz) 1+1 SD System...

- Page 34 Submission Prohibited NEC Internal Use Only 5-12 ODU MOUNTING Procedure 5-1 Change of Polarization of Antenna (1)) ODU Direct Mounting Type Antenna (ANDREW example #1) Notes The details are referred to the installation manual which is attached to the antenna. The installation or removal of the antenna requires qualified experienced personnel.

- Page 35 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-13 Holding the feed with hand, rotate the feed 90 degrees, Check that the aperture part of the Transition hub is rotated 90 degrees, then fix it with the screws that were loosened in step 2,...

- Page 36 Submission Prohibited NEC Internal Use Only 5-14 ODU MOUNTING Rotate the transition hub 90 degrees until timing pin locates in timing concavity, Transition hub Transition hub Transition Hub Timing Pin Vertical Polarized Application Horizontally Polarized Application Tighten six screws when transition hub is located. (Tightening torque is 5.0 N·m ±10%.

- Page 37 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-15 Antenna top Horizontal Vertical 4 screws (M3) Polarization H Polarization V Installation NWD-107460-02E...

- Page 38 Plate marked with H Plate marked with V Notes When the ODU is mounted on to the NEC Hybrid/CouplerHybrid/ Coupler, only V polarization is applied. When the Waveguide or coaxial cable is connected between the ODU and antenna, the ODU in V polarization for up position is recommended for installation.

- Page 39 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-17 Guide pin Plate marked with V V Polarization Plate marked with H Guide pin H Polarization 13-38 GHz ODU V/H Polarization Conversion Installation NWD-107460-02E...

- Page 40 Submission Prohibited NEC Internal Use Only 5-18 ODU MOUNTING 5.1.2 With Hybrid/Coupler This section explains the antenna direct mounting type ODU installation with Hybrid/Coupler. Mounting Note The details are referred to the installation manual which is attached to the antenna.

- Page 41 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-19 [A] 10-38 GHz Hybrid/Coupler Fix the bracket and handle to the Hybrid/Coupler, Handle PUSH M5 Head cap screw M5x12(10ea) Bracket Hybrid/Coupler Note Tightening torque is 3.0 N·m ±10%. Check the polarization and install the Hybrid/Coupler to the antenna by tightening the M6 screws (four locations).

- Page 42 Submission Prohibited NEC Internal Use Only 5-20 ODU MOUNTING Insert the O-rings to the two ODU ports of the Hybrid/Coupler, Install the two ODUs with hex screws (four locations) using the Allen key wrench. Note Be careful not to damage the O-rings (Hybrid/Coupler).

- Page 43 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-21 For 26-38 GHz ODU O-ring O-ring Note Tightening torque is 4.0 N·m ±10% Installation NWD-107460-02E...

- Page 44 Submission Prohibited NEC Internal Use Only 5-22 ODU MOUNTING Demounting from Hybrid/Coupler Loosen the four (or six) bolts fixed the ODU, Then demount the ODU. Note When demounting the ODU from Hybrid/Coupler, mount the attached SHORT PLATE to the demounted port of the Hybrid/Coupler to avoid RF power leaking from the hybrid/coupler and for waterproofing.

- Page 45 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-23 Change of Polarization of Hybrid/Coupler Note The hybrid/coupler is set to V-polarization when shipped from the factory. If you change the polarization from V to H, loosen two screws, rotate the transition hub and put it to the Hybrid/Coupler.

- Page 46 Submission Prohibited NEC Internal Use Only 5-24 ODU MOUNTING [B] 7/8 GHz Hybrid This Hybrid/coupler is designed to be attached to 0.6 to 1.8 m antennas with interface for direct mounting of ODU. Hybrid assembly Spring Washer M5 (8ea.) Hexagon Socket Head Cap Screw M5 x 14 (8ea.)

- Page 47 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-25 Installation to antenna Flat Washer M6 (4ea.) Tighten the each screw Antenna Spring Washer M6 (4ea.) equally and carefully by wrench at diagonal position. Hexagon Socket Head Cap Screw M6 x 20 (4ea.)

- Page 48 Submission Prohibited NEC Internal Use Only 5-26 ODU MOUNTING Attachment of Standby ODU NEC ODU "V" direction of ODU (Main ODU) O-Ring (Packing) Top View NEC ODU (Standby ODU) Table 5-2 Hybrid Parts List Parts Name Q’ty Hybrid Support O-Ring...

- Page 49 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-27 [C] 7/8 GHz Coupler This Hybrid/coupler is designed to be attached to 0.6 to 1.8 m antennas with interface for direct mounting of ODU. Coupler assembly Spring Washer M5 (8ea.) Hexagon Socket Head Cap Screw M5 x 14 (8ea.)

- Page 50 Submission Prohibited NEC Internal Use Only 5-28 ODU MOUNTING Installation to antenna Flat Washer M6 (4ea.) Tighten the each screw Antenna Spring Washer M6 (4ea.) equally and carefully by wrench at diagonal position. Hexagon Socket Head Cap Screw M6 x 20 (4ea.)

- Page 51 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-29 Attachment of Standby ODU NEC ODU "V" direction of ODU (Main ODU) O-Ring (Packing) Top View NEC ODU (Standby ODU) Table 5-3 Coupler Parts List Parts Name Q’ty Coupler Support O-Ring...

- Page 52 Submission Prohibited NEC Internal Use Only 5-30 ODU MOUNTING [D] 13/15 GHz Hybrid, 15 GHz Coupler This Hybrid/coupler is designed to be attached to 0.2 to 1.8 m antennas with interface for direct mounting of ODU. Hybrid/Coupler assembly Spring Washer M5 (8ea.)

- Page 53 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-31 Installation to antenna Flat Washer M6 (4ea.) Spring Washer M6 (4ea.) Tighten the each screw Antenna equally and carefully by wrench at diagonal Hexagon Socket position. Head Cap Screw M6 x 20 (4ea.)

- Page 54 Submission Prohibited NEC Internal Use Only 5-32 ODU MOUNTING Attachment of Standby ODU Top View NEC ODU (Main ODU) O-Ring (Packing) NEC ODU "V" direction of ODU (Standby ODU) Table 5-4 Hybrid/Coupler Parts List Parts Name Q’ty Hybrid/Coupler Support O-Ring...

- Page 55 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-33 [E] 18/23 GHz Hybrid This Hybrid is designed to be attached to 0.2 to 1.8 m antennas with interface for direct mounting of ODU. Hybrid assembly Spring Washer M5 (8ea.) Hexagon Socket Head Cap Screw M5 x 12 (8ea.)

- Page 56 Submission Prohibited NEC Internal Use Only 5-34 ODU MOUNTING Installation to antenna Flat Washer M6 (4ea.) Tighten the each screw Spring Washer M6 (4ea.) Antenna equally and carefully by wrench at diagonal Hexagon Socket position. Head Cap Screw M6 x 20 (4ea.)

- Page 57 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-35 Attachment of Standby ODU NEC ODU Top View (Main ODU) O-Ring (Packing) NEC ODU "V" direction of ODU (Standby ODU) Table 5-5 Hybrid Parts List Parts Name Q’ty Hybrid Support O-Ring...

- Page 58 Submission Prohibited NEC Internal Use Only 5-36 ODU MOUNTING 5.1.3 With TX Span Attenuator This section explains the antenna direct mounting type ODU installation with TX Span Attenuator (TX SPAN ATT). Mounting Check the polarization of the antenna connection unit of the TX ATT (Refer to "Change of Polarization of TX ATT"...

- Page 59 NEC Internal Use Only ODU MOUNTING 5-37 Attachment of ODU Hexagon socket ODU should be attached head cap screw M6 by turning “V” up. (Supplied by NEC with ODU) O-ring TX ATT (Packing) Top view O-ring (Packing) Antenna TX ATT ODU connection unit Note Tightening torque is 4.0 N·m ±10%.

- Page 60 Submission Prohibited NEC Internal Use Only 5-38 ODU MOUNTING Change of Polarization of TX SPAN ATT Note The TX ATT is set to V-polarization when shipped from the factory. If you change to H polarization, loosen two screws, rotate the antenna connection...

- Page 61 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-39 5.1.4 With Ortho-Mode Transducer This section explains the antenna direct mounting type ODU installation with Ortho- Mode Transducer (OMT). There are two types of O-rings for antenna mounting to the OMT depending on the frequency band.

- Page 62 Submission Prohibited NEC Internal Use Only 5-40 ODU MOUNTING For the antenna direct mounting of the ODU, following OMT is used. Interface WG Inner Frequency Frequency Interface Dia. (mm) Band Range (GHz) (ODU Side) (ANT Side) 10.4 − 11.7 GHz 11 G 18.0...

- Page 63 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-41 Fix the OMT to the antenna by tightening them with M6 screws (four locations), M6 Screw Flat washer M6 Guide pin Short plate ODU Port O-ring O-ring Notes 1. Be careful not to damage the O-ring.

- Page 64 Submission Prohibited NEC Internal Use Only 5-42 ODU MOUNTING Plate marked with V RX LEV RX LEV ODU (10/11 GHz) Main Master Sub Master Plate marked with V ODU (13-38 GHz) Main Master Sub Master Insert the O-rings to the two ODU ports of the OMT (see figure in step 9.),...

- Page 65 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-43 Fix the two ODUs with hex screws (four locations) using the allen key wrench. Note Be careful not to damage the O-rings. Hex screw H Polarization side O-ring O-ring V Polarization side Note Tightening torque is 4.0 N·m ±10%.

- Page 66 Submission Prohibited NEC Internal Use Only 5-44 ODU MOUNTING Cautions: 1. Tighten all screws with lighter torque at first, then full torque as specified. 2. When either ODU is demounting for ODU replacing or other reasons, fix the attached short plate to the demounted port of the OMT to avoid leaking of RF power from the OMT and for waterproof.

- Page 67 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-45 5.2 Feeder Connection 5.2.1 For Coaxial Cable Connection 6/7/8GHz ODU MOUNTING BRACKET INSTALLATION This Mounting Bracket is designed in order to install 6/7/8 GHz ODU with N-type connector or Waveguide interface to a pole. The diameter of the pole is from 48.5 to 114.3 millimeters.

- Page 68 Submission Prohibited NEC Internal Use Only 5-46 ODU MOUNTING Standard Installation Reverse Installation A nut is assembled to a stud bolt until a nut has come to a complete stop, Assembly of the Holder-1 (2 sets) Stud bolt M8 Hexagon nut M8...

- Page 69 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-47 Fix the two Holder-1 to the Bracket at four bolts, Assembly of the Bracket Holder-1 Assembly Bracket Flat washer M6 (4 ea) Spring lock washer M6 (4 ea) Hexagon socket head screw M6×16 (4 ea)

- Page 70 Submission Prohibited NEC Internal Use Only 5-48 ODU MOUNTING Mount the ODU on to the Bracket and tighten four bolts (M6) at upper and lower parts of the ODU, Attachment of the ODU Hexagon socket head screw M6 Note Tightening torque is 4 N·m ±10%.

- Page 71 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-49 5.2.2 For Waveguide Connection 10-38 GHz ODU MOUNTING BRACKET INSTALLATION This Mounting Bracket is designed in order to install 10-38 GHz ODU with antenna direct mount interface to a pole. The diameter of the pole is from 48.5 to 114.3 millimeters.

- Page 72 Submission Prohibited NEC Internal Use Only 5-50 ODU MOUNTING Standard Installation Reverse Installation A nut is assembled to a stud bolt until a nut has come to a complete stop, Assembly of the Holder-1 (2 sets) Stud Bolt M8 Hexagon Nut M8...

- Page 73 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-51 Fix the two Holder-1 to the Bracket at four bolts, Assembly of the Bracket Holder-1 Assembly Bracket (with Adapter) Flat Washer M6 (4 ea) Spring Lock Washer M6 (4 ea) Hexagon Socket Head Screw M6×16 (4 ea)

- Page 74 Submission Prohibited NEC Internal Use Only 5-52 ODU MOUNTING Note Since a bolt projects from a Holder when a pole diameter is small, please attach the Cap to a bolt end. Mount the ODU on to the Bracket and tighten four bolts (M6) at upper and lower parts of the ODU.

- Page 75 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-53 Connect the waveguide to the adapter of the mounting bracket, Example Connection of the Waveguide Pole Flexible waveguide Antenna Flexible waveguide Flexible waveguide O-ring (for waveguide) Screw of waveguide connecting Table 5-8 Waveguide Flange Type...

- Page 76 Submission Prohibited NEC Internal Use Only 5-54 ODU MOUNTING 5.2.3 For Waveguide Connection with Hybrid 18/23 GHz Hybrid (FI) This Hybrid is designed to be connect to waveguide with interface for direct mounting of ODU. (Waveguide flange type: Hybrid side-PBR220, Waveguide side- UBR220.)

- Page 77 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-55 Installation to pole mount, Case-1 Hexagon nut M6 (Double) (8 ea)* Hexagon head screw M6 × 35 (4 ea)* Flat washer M6 (4 ea)* Short Plate In case you remove ODU, Please attach this Short plate to the ODU port.

- Page 78 Submission Prohibited NEC Internal Use Only 5-56 ODU MOUNTING Attachment of standby ODU, ODU (Main ODU) Pole mount O-ring I/D φ32 (Packing) ODU (Standby ODU) ODU should be attached by turning “V” up. Top view Connection of waveguide, Hybrid Pole mount Do not Remove O-ring I/D φ32...

- Page 79 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-57 Caution: Be careful not to damage the Hybrid. Connection part will be damaged if excessive power is applied to the Hybrid by Waveguide. Table 5-9 Hybrid (Fl) Parts List (for Mounting Bracket) Parts Name Q’ty...

- Page 80 Submission Prohibited NEC Internal Use Only 5-58 ODU MOUNTING Attachment of main ODU, O-ring I/D φ32 Hexagon socket head (Packing) cap screw M6 ODU (Main ODU) Connection part details Mounting bracket ODU should be attached O-ring I/D φ32 by turning “V” up.

- Page 81 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-59 Connection of waveguide, Mounting bracket Hybrid O-ring I/D φ15.6 (Packing) Do not remove. Hexagon head screw with washer M3 × 10 (4 ea) Flexible waveguide Flange type UBR220 Waveguide flange Flange type PBR220...

- Page 82 Submission Prohibited NEC Internal Use Only 5-60 ODU MOUNTING 5.3 Other Mounting 5.3.1 Wall Mounting For the antenna direct mounting type ODU, wall mounting installation is explained in following procedure. Using a center punch and hammer, mark the drilling holes for the ODU wall mount bracket.

- Page 83 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-61 Remove debris from the specified hole and insert a plug-bolt into it, Anchor bolt Make sure to insert the plug-bolt fully, Tighten hardly the bolt using a wrench or monkey wrench, Note Anchor bolts of M10 bolt shall be prepared by the customer.

- Page 84 Submission Prohibited NEC Internal Use Only 5-62 ODU MOUNTING Fix the ODU wall mounting bracket to the wall with the six bolts (M6) of the anchor volt, Flat washer* Spring washer* Flange adaptor Bolt* Note The BOLT, FLAT WASHER and SPRING WASHER are of the Anchor bolt.

- Page 85 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-63 10 Connect the wave guide to the transducer for the ODU. Waveguide O-ring ODU 10/11 GHz) Bolt (M4) Washer Spring washer Notes Tightening torque is 1.4 N·m ±10% (up to 15 GHz).

- Page 86 Submission Prohibited NEC Internal Use Only 5-64 ODU MOUNTING 5.3.2 Rack Mounting For the antenna direct mounting type ODU, rack mounting installation is explained in following procedure. Fix the ODU rack mounting bracket into the 19-inch rack using the six fixing...

- Page 87 Submission Prohibited NEC Internal Use Only ODU MOUNTING 5-65 Connect the wave guide to the transducer for the ODU. Waveguide O-ring Bolt* Washer Spring washer Notes M4: Up to 15 GHz. M3: 18 GHz or higher. Tightening torque is 1.4 N·m ±10% (up to 15 GHz).

- Page 88 Submission Prohibited NEC Internal Use Only 5-66 ODU MOUNTING 5.4 Hybrid Combiner Installation When you attach two Hybrids to one Dual pol. antenna, for 1+1 or 2(1+1) system in 6/7/8 GHz rotate the antenna 90 degree counter clockwise, as shown below, to avoid hitting the hybrids to the antenna pole and its structures if necessary.

- Page 89 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6. CABLE TERMINATION In this section, list of tools, materials and the method for cable termination are described. The list of applicable cable is shown in Table 6-1. Table 6-1 List of Applicable Cable...

- Page 90 Submission Prohibited NEC Internal Use Only CABLE TERMINATION The necessary tools and materials are summarized in Table 6-2. Table 6-2 Tools and Materials List Name Remarks Knife Measure/Ruler Cutter Nipper File Spanner (14 mm, 16 mm) For IF coaxial connector...

- Page 91 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6.1 5D Coaxial Cable Procedure 6-1 TNC-P Connector used for IDU IF IN/OUT (L-angle:TNC150(R0)) Outlines of parts [Applicable cable: 5D-FB-E] Cable jacket Clamp Clamp nut Aluminum tape Connector body Center conductor Braided wire Insulator •...

- Page 92 Submission Prohibited NEC Internal Use Only CABLE TERMINATION • knife Tools • cutter • measure, etc. Insertion of parts. (1) The clamp is inserted as shown. Braided wire is turned back to clamp side. Clamp Braided wire Aluminum tape Center Conductor...

- Page 93 Submission Prohibited NEC Internal Use Only CABLE TERMINATION Remove of braided wire, insulator. (1) The insulator and an aluminum tape are cut along an end face of turned up braided wire. Aluminum tape Insulator Center conductor Note Do not damage the braided wire and the center conductor.

- Page 94 Submission Prohibited NEC Internal Use Only CABLE TERMINATION (2) The braided wire is cut according to flange of clamp. Center conductor Flange Aluminum tape Braided wire Center conductor Flange • cutter Tools • nipper NWD-107460-02E Installation...

- Page 95 Submission Prohibited NEC Internal Use Only CABLE TERMINATION Center conductor processing. (1) Remove of the center conductor as shown. (2) Chamfer the center conductor. Center conductor 1 mm 6 mm ± 1 Center conductor • nipper Tools • file, etc.

- Page 96 Submission Prohibited NEC Internal Use Only CABLE TERMINATION Connector assembly (1) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers.

- Page 97 Submission Prohibited NEC Internal Use Only CABLE TERMINATION (b) Tightening only of clamp nut by finger. * Keep the hold of the cable. Do not turn connector body. Hold of connector body by spanner. (d) Hold of cable Installation NWD-107460-02E...

- Page 98 Submission Prohibited NEC Internal Use Only 6-10 CABLE TERMINATION (e) Set the torque spanner. Tightening only of clamp nut by torque spanner. Tightening the connection to the torque value of 9 to 11 N·m. Holding only 14mm 9-11 N·m 14mm...

- Page 99 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-11 Procedure 6-2 TNC-P Connector used for IDU IF IN/OUT (L-angle: 300PTR-C-NC) Outlines of parts [Applicable cable: 5D-FB-E] Connector body Parts A Parts B Aluminum tape Cable jacket Center conductor Insulator Braided wire •...

- Page 100 Submission Prohibited NEC Internal Use Only 6-12 CABLE TERMINATION Note Do not damage the center conductor. • cutter Tools • measure etc., Insertion of parts Make the braided wire small and sharp at the front; Install parts B and parts A revolving as onto cable without damaging the braided wire.

- Page 101 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-13 (3) The braided wire is cut according to outer of parts A. • scissors Tools • nipper • tweezers Center conductor processing Chamfer the center conductor at a 45º angle. º...

- Page 102 Submission Prohibited NEC Internal Use Only 6-14 CABLE TERMINATION Connector assembly (1) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers. Tighten the connection to the torque value of 60 to 80 lb-in (6.8 to 9.0 N·m).

- Page 103 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-15 Procedure 6-3 TNC-P Connector used for IDU IF IN/OUT (L-angle:TNC156(R0)) Outlines of parts [Applicable cable: 5D-FB-E] Connector body Cable jacket Clamp Clamp nut Aluminum tape Center conductor Braided wire Insulator •...

- Page 104 Submission Prohibited NEC Internal Use Only 6-16 CABLE TERMINATION Insertion of parts. (1) The clamp is inserted as shown. Braided wire is turned back to clamp side. Clamp Braided wire Aluminum tape Center Conductor Insulator Defective example The amount of the braid is not uniform.

- Page 105 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-17 Remove of braided wire, insulator. (1) The insulator and an aluminum tape are cut along an end face of turned up braided wire. Alminum tape Note Do not damage the braided wire and the center conductor.

- Page 106 Submission Prohibited NEC Internal Use Only 6-18 CABLE TERMINATION Center conductor processing. (1) Remove of the center conductor as shown. (2) Chamfer the center conductor. Center conductor 1 mm Center conductor 5 mm ± 1 • nipper Tools • file, etc.

- Page 107 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-19 (2) Tighten the connection to the torque value of 10 N·m. Clamp nut 10 N·m 12mm 16mm (3) Confirm the total length* of the connector. total length :31.4 ~ 31.7 mm * 31.4 ~ 31.7 mm...

- Page 108 Submission Prohibited NEC Internal Use Only 6-20 CABLE TERMINATION Procedure 6-4 N-P Connector used for ODU IF IN/OUT (L-angle: 300PNR-C-NC) Outlines of parts Applicable cable: 5D-FB-E] Cable jacket Aluminum tape (Connector body) (Parts A) (Parts B) Clamp nut Center conductor...

- Page 109 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-21 (3) Remove all insulator/tape residue from the center conductor. Note: Do not damage the center conductor. • cutter Tools • measure etc., Insertion of parts Make the braided wire small and sharp at the front;...

- Page 110 Submission Prohibited NEC Internal Use Only 6-22 CABLE TERMINATION (2) Fold the braided wire around parts A. (3) The braided wire is cut according to outer of parts A. • scissors Tools • nipper • tweezers Center conductor processing Chamfer the center conductor at a 45º angle.

- Page 111 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-23 Connector assembly (1) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers. Tighten the connection to the torque value of 60 to 80 lb-in (6.8 to 9.0 N·m).

- Page 112 Submission Prohibited NEC Internal Use Only 6-24 CABLE TERMINATION Procedure 6-5 N-P Connector used for ODU IF IN/OUT (Straight: 300PNM-C-NC) [Applicable cable: 5D-FB-E] Outlines of parts Parts B (Clamp nut) Parts A Connector body Cable jacket Aluminum tape Center conductor...

- Page 113 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-25 (3) Remove all insulator/tape residue from the center conductor. Note: Do not damage the center conductor. • cutter Tools • measure etc., Insertion of parts Make the braided wire small and sharp at the front;...

- Page 114 Submission Prohibited NEC Internal Use Only 6-26 CABLE TERMINATION (2) Fold the braided wire around parts A. (3) The braided wire is cut according to outer of parts A. • scissors Tools • nipper • tweezers Center conductor processing Chamfer the center conductor at a 45º angle.

- Page 115 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-27 • cutter Tools • measure • file, etc. Connector assembly (1) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers.

- Page 116 Submission Prohibited NEC Internal Use Only 6-28 CABLE TERMINATION Procedure 6-6 N-P Connector used for ODU IF IN/OUT (Straight: N435(R0)) Outlines of parts [Applicable cable: 5D-FB-E] Cable jacket Washer Aluminum tape Gasket Clamp1 Connector body Clamp2 Center conductor Braided wire...

- Page 117 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-29 Center conductor processing (1) Braided wire is disentangled. Braided wires which became straight wires are turned back to clamp1 side. The braided wires are cut according to step of clamp1. Step of clamp1 (2) Remove of insulator and aluminum tape as shown without damaging the center conductor.

- Page 118 Submission Prohibited NEC Internal Use Only 6-30 CABLE TERMINATION Connector assembly (1) The clamp2 is inserted between the aluminum tape and the braided wire. Clamp2 (2) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers.

- Page 119 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-31 (3) The gap of the connector body and clamp nut is confirmed. (*) Gap: 2.2 to 2.7 mm (*): Check Point • spanner (16 mm) Tools • torque spanner (16 mm) •...

- Page 120 Submission Prohibited NEC Internal Use Only 6-32 CABLE TERMINATION 6.2 8D Coaxial Cable Procedure 6-7 TNC-P Connector used for IDU IF IN/OUT (L-angle: TNC141(R0)) Outlines of parts [Applicable cable: 8D-FB-E] Aluminum tape Connector body Cable jacket Spacer Washer Insulator Center conductor...

- Page 121 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-33 Insertion of parts. (1) The clamp are inserted in the cable. (2) The braided wire is expanded a little. The cord tube is inserted between the aluminum tape and the braided wire.

- Page 122 Submission Prohibited NEC Internal Use Only 6-34 CABLE TERMINATION Notes 1. Do not damage the braided wire. 2. Do not damage the center conductor. (brr etc.,) Insertion of contact. (1) A spacer is inserted in a central conductor and contact is inserted.

- Page 123 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-35 Insertion of parts. (1) The clamp are inserted in the cable. (2) The braided wire is expanded a little. The cord tube is inserted between the aluminum tape and the braided wire.

- Page 124 Submission Prohibited NEC Internal Use Only 6-36 CABLE TERMINATION Notes 1. Please note the position of the cord tube. 2. Do not damage the braided wire. 3. Do not damage the center conductor (burr etc.). Insertion of contact. (1) The clamp is moved to the cord tube side.

- Page 125 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-37 (2) The washer and clamp nut are moved to the connector side, and it tightens. The tightening torque of the clamp nut is 8 to13 N·m. Clamp nut Washer 16 mm 8-13 N·m...

- Page 126 Submission Prohibited NEC Internal Use Only 6-38 CABLE TERMINATION Procedure 6-8 N-PConnector used for ODU IF IN/OUT (L-angle: N-LP-8DFB(B)) First fit the tying metal, washer and gasket on the cable, [Applicable cable: 8D-FB-E] Tying Metal Washer Cable Gasket Strip back the cable sheath, taking care not to damage the braided shield, and fit...

- Page 127 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-39 Cut the aluminum foil and inner insulator away along the bushing and retain the inner conductor, Taper the edge of the center conductor using a file as shown in the enlarged view...

- Page 128 Submission Prohibited NEC Internal Use Only 6-40 CABLE TERMINATION 10 Tighten the tying metal by wrench using the wrench points (Tighten with torque of 4 to 10 N·m). Less than 0.1 mm (Usually no gaps) Wrench point NWD-107460-02E Installation...

- Page 129 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-41 Procedure 6-9 N-P Connector used for ODU IF IN/OUT (Straight: N416(R0)) Outlines of parts [Applicable cable: 8D-FB-E] Cable jacket Gasket Washer Connector body Aluminum tape Clamp1 Center conductor Braided wire Insulator Clamp nut •...

- Page 130 Submission Prohibited NEC Internal Use Only 6-42 CABLE TERMINATION Center conductor processing (1) Braided wire is disentangled. Braided wires which became straight wires are turned back to clamp1 side. The braided wires are cut according to step of clamp1. Step of clamp1 (2) Remove of insulator and aluminum tape as shown without damaging the center conductor.

- Page 131 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-43 Connector assembly (1) The cable center conductor must be straight and aligned with the connector inner contact. Insert the cable into the connector body until stopped; the center conductor must be inserted into the connector inner contact fingers. Tighten the connection to the torque value of 9 to 11 N·m.

- Page 132 Submission Prohibited NEC Internal Use Only 6-44 CABLE TERMINATION 6.3 Other Cable Procedure 6-10 Power Supply Cables with AMP Housing & Socket Contacts Note Do not bend this part. Power connector Socket contact Remove 3.0 to 3.5 mm of insulation,...

- Page 133 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-45 Squeeze the handle of the hand crimping tool, insert cable into socket contact, The cable should fit, so insulation and bare wire are arranged as shown, Squeeze the handle of the hand crimping tool until the ratchet is released,...

- Page 134 Submission Prohibited NEC Internal Use Only 6-46 CABLE TERMINATION Procedure 6-11 120 ohms Balanced Interface with D-Sub Connector Notes Use D-sub connectors of less than 16 mm in height as illustrated below. D-sub connector Height Use D-sub 44-pin connector for the CTRL of less than 57 mm in width as illustrated below.

- Page 135 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-47 Remove 4 mm of insulation from the end of the wire, CONFORMING WIRE SOCKET CONTRACT AWG#20-24: CD-PC-111 AWG#24-28: CD-PC-121 4 mm Wire Insert the cable into the socket contact, Socket contact...

- Page 136 Submission Prohibited NEC Internal Use Only 6-48 CABLE TERMINATION Recheck that the wire position is as shown in step 5 before crimping the socket contact (see illustration below), Wire side Socket contact Wire Wind the metallic shield tape over the braided shield, Metallic shield tape Set the cable into the plug case as shown in figure below.

- Page 137 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-49 11 Referring to circle B, insert each wire to the specified position (Refer Interface Terminals and Jacks for IDU in Section II OPERATING EQUIPMENT.). Insert the socket contacts into the upper and lower row positions while taking care that...

- Page 138 Submission Prohibited NEC Internal Use Only 6-50 CABLE TERMINATION 12 Fix the plug case with two screws, as shown in the figure. Screw Plug case Procedure 6-12 Auxiliary Signal Interface with D-Sub High Density Crimp Contacts Assembly Connector The following explains how to assemble high density crimp contacts used for HARTING hand crimp tool as an example.

- Page 139 Submission Prohibited NEC Internal Use Only CABLE TERMINATION 6-51 Stranded wire Jacket Jacket Applicable wire size: 0.14 - 0.22 mm (AWG26 - 24), φ stranded, maximum insulation: 1.38 mm Stamped male contacts: 09 56 000 8175 (Level S4), High density male connectors: 09 56 300 5601 (#44) −...

- Page 140 Submission Prohibited NEC Internal Use Only 6-52 CABLE TERMINATION Take out the crimped contacts from the chamber. Check if it should not be scratched or transformed, After crimping the stranded wire to the contact using a hand tool, insert the contact into the contact chamber with the tool, working from the wiring side, You can here the contacts snap home, audible “click”,...

- Page 141 Submission Prohibited NEC Internal Use Only WIRING and FORMING 7. WIRING and FORMING Procedure Connect cables for, signal interface, power supply, IF IN/OUT and ground to the proper connector of the IDU. (1) Connect ground cable to the ground terminal.

- Page 142 Submission Prohibited NEC Internal Use Only WIRING and FORMING Straight Type Caution When connecting the IF cable to the ODU, tighten the N-male connector with engage connector nut only using fingers and holding the cable with another hand. IF cable...

- Page 143 Submission Prohibited NEC Internal Use Only WIRING and FORMING Straight Type Caution Tighten the TNC-male connector of IF cable to the IDU with engage connector nut only using fingers and holding the cable with another hand. IF cable L-Angle Type (*) Tighten the engage connector nut only for the L-angle connector also.

- Page 144 Submission Prohibited NEC Internal Use Only WIRING and FORMING Precaution for connecting the IF cable with a L-angle connector to the IDU (a) Wrapping connector and cable by vinyl tape for protection. After terminating the IF cable with a L-angle connector.

- Page 145 Submission Prohibited NEC Internal Use Only WIRING and FORMING (b) Preparation for connecting the IF cable to the IDU. When connecting the IF cable to the IDU, turn the IF Cable itself to match face to face their interface points between the IF cable and the IDU.

- Page 146 Submission Prohibited NEC Internal Use Only WIRING and FORMING IDU Cable Wiring and Forming Take a suitable bend radius. Cable Binder Fix the cables to the mounting rack with cable binder. Fig. 7-1 Cable Wiring and Forming NWD-107460-02E Installation...

- Page 147 Submission Prohibited NEC Internal Use Only FRAME GROUNDING 8. FRAME GROUNDING In mounting the IDU and ODU, perform frame grounding. The location of the frame grounding in each IDU and ODU is shown in Fig. 8-1, and the connection for frame grounding is shown in Fig.

- Page 148 Submission Prohibited NEC Internal Use Only FRAME GROUNDING Lighting rod Protect area Outdoor earth ground terminal (Existing or customer supplied) Coaxial cable Earth line Indoor earth ground terminal Rack Use a copper grounding conductor to ground the rack. The grounding conductor to the CO Earth line GND be connected to the rack.

- Page 149 GROUND naked wire. LEVEL Notes NEC recommends that frame ground of ODU should be connected to earth line as NEC’s standard installation. Earth Ground Point of tower Frame Ground terminal of the IDU (5 mm square cable (means more than 2.5 mm diameter cable (AWG #10) is recommended to apply for the earth grounding.

- Page 150 Submission Prohibited NEC Internal Use Only FRAME GROUNDING This page is intentionally left blank. NWD-107460-02E Installation...

- Page 151 Submission Prohibited NEC Internal Use Only WATERPROOF PROTECTION 9. WATERPROOF PROTECTION After cable connection, the following parts should be wrapped by self-bonding tape for waterproof (see Fig. 9-1). Caution Before connecting the IF cable between the IDU and ODU, using the circuit tester, check that the resistance of the I/F cable between center conductor and insulation is more than 100 MΩ...

- Page 152 Submission Prohibited NEC Internal Use Only WATERPROOF PROTECTION For ODU (6-11 GHz) For ODU (13-38 GHz) (Bottom View) This part should be wrapped the self-bonding tape tightly, twice or more around the IF cable connector and IF IN/OUT connector of the ODU for IFL connector waterproof.

- Page 153 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-1 10. ANTENNA ORIENTATION After the initial setup has been completed, an antenna orientation will be performed between two stations according to the following procedure . Procedure Apparatus Digital Multimeter with test leads or X0818 PASOLINK Monitor Wrench...

- Page 154 Submission Prohibited NEC Internal Use Only 10-2 ANTENNA ORIENTATION At each station, adjust the azimuth and elevation angle of the antenna alternately so that the measured voltage becomes maximum, Note The relation of the RX INPUT LEVEL versus RX LEVEL MON(V) is shown below.

- Page 155 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-3 PASOLINK MONITOR DIGITAL MULTIMETER RX LEV MON RX LEV/OW IN RX LEV ODU (6-11 GHz) RX LEV MON − ODU (13-38 GHz) View A Notes The RX LEV MON terminal on the ODU (conformed to IEC61169-24).

- Page 156 Submission Prohibited NEC Internal Use Only 10-4 ANTENNA ORIENTATION Safety Guideline for Microwave Radiation Hazard The Microwave and Millimetre-wave that iPASOLINK series are treating is very small radiation level and never been reported to effect human health. But advanced countries about health hazard have started to regulate the radiation levels. In case of EU country, it is specified by EN50385.

- Page 157 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-5 Calculation example 1, (90 degree side of antenna) PASOLINK = 18 GHz/+23 dBm, Antenna diameter = 0.6 m, 0 degree antenna gain = 39 dBi, 90 degrees side antenna gain = −24 dBi, (90 degrees attenuation = −63 dB), Distance = 0.1 m...

- Page 158 Submission Prohibited NEC Internal Use Only 10-6 ANTENNA ORIENTATION ANTENNA DIRECT MOUNTING TYPE A. USING ANDREW VHLP TYPE BRACKET Azimuth Angle Adjustment Loosen bolts (1 in Fig. 10-2), Adjust the azimuth angle by adjusting bolt (2 in Fig. 10-2), Secure bolts loosened in step A-1 , Elevation Angle Adjustment Loosen bolts (3 in Fig.

- Page 159 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-7 Elevation Angle Adjustment Loosen bolt(s) (3 in Fig. 10-3), Adjust the elevation angle by adjusting the nuts (4 in Fig. 10-3), Secure nut loosened in step B-1, Secure nuts loosened in step B-4.

- Page 160 Submission Prohibited NEC Internal Use Only 10-8 ANTENNA ORIENTATION 1. Loosen (1/4 turn) bolts for adjusting azimuth 2. Adjust azimuth. 3. Loosen (1/4 turn) bolts for adjusting elevation. 4. Adjust elevation. 0.6 φ m Antenna Fig. 10-4 Location of Adjusting Nuts and Bolts (RFS C-Mount type bracket)

- Page 161 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-9 At each station, restore the “Antenna Alignment Mode” to “off” using the LCT, At each station, reset control items to original using LCT, At each station, restore the “MAINT Mode” to “off” position using the LCT,...

- Page 162 Submission Prohibited NEC Internal Use Only 10-10 ANTENNA ORIENTATION Rotation indicator Screw 2 Screw 1 Pole Screw 3 A. RFS SB1 type bracket B. RFS C-Mount type bracket Fig. 10-5 Location of Adjusting Nuts and Bolts (RFS C-Mount type bracket)

- Page 163 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-11 WAVEGUIDE CONNECTION TYPE Azimuth Angle Adjustment (Waveguide Connection Type) Note Take care that the flexible waveguide is not forcedly twisted by rotating the antenna. When the HS/SD system is configured, alternately switchover the transmitter to the other channel (No.1 or No.2) at the opposite station and repeat adjustment of...

- Page 164 Submission Prohibited NEC Internal Use Only 10-12 ANTENNA ORIENTATION Elevation Angle Adjustment (Waveguide Connection Type) Make sure that all strut attachment hardware is loosened, Loosen bolts indicated by arrows in Fig. 10-7, Loosen jam nuts and rotate turnbuckle-2 in Fig. 10-7 so that the RX LEVEL MON voltage obtains the maximum value, Carefully, tighten turnbuckle-2 jam nuts and bolts indicated by arrows in Fig.

- Page 165 Submission Prohibited NEC Internal Use Only ANTENNA ORIENTATION 10-13 XPD Adjustment (Waveguide Connection Type) Note This XPD adjustment using cross-polarization signal should be done more carefully than using co-polarization signal because XPD changes sharply in the axial direction. At opposite station, turns the ODU of the Sub Master channel power OFF (for both No.1 and No.2 Sub Master channels in 1+1 system),...

- Page 166 Submission Prohibited NEC Internal Use Only 10-14 ANTENNA ORIENTATION This page is intentionally left blank. NWD-107460-02E Installation...