Mitsubishi Electric PFFY-P20VKM-E Service Manual

Series pffy floor standing

Hide thumbs

Also See for PFFY-P20VKM-E:

- Installation manual (84 pages) ,

- Operation manual (40 pages) ,

- Technical & service manual (34 pages)

Table of Contents

Advertisement

Quick Links

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Series PFFY

[Model names]

PFFY-P20VKM-E

PFFY-P25VKM-E

PFFY-P32VKM-E

PFFY-P40VKM-E

INDOOR UNIT

NOTE:

This service manual describes technical data of the indoor units.

•As for outdoor units refer to outdoor unit's service manual.

•RoHS compliant products have <G> mark on the spec name plate.

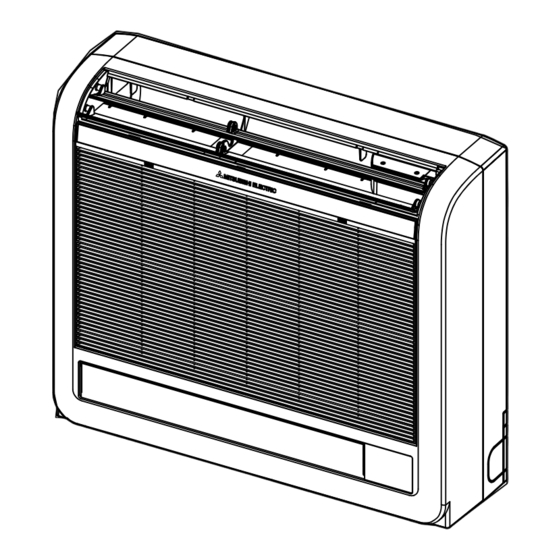

Floor Standing

[Service Ref.]

PFFY-P20VKM-E

PFFY-P25VKM-E

PFFY-P32VKM-E

PFFY-P40VKM-E

Indication of model name

R410A

R407C

CONTENTS

1. SAFETY PRECAUTION··························2

2. PART NAMES AND FUNCTIONS ··········6

3. SPECIFICATION ·····································8

4. NOISE CRITERIA CURVES··················10

5. AIR OUTLET SELECTION····················11

6. OUTLINES AND DIMENSIONS ············12

7. WIRING DIAGRAM ·······························13

8. REFRIGERANT SYSTEM DIAGRAM······14

9. TROUBLE SHOOTING ·························15

10. DISASSEMBLY PROCEDURE·············23

11. RoHS PARTS LIST ·······························28

July 2006

No. OC404

R22

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric PFFY-P20VKM-E

-

Page 1: Table Of Contents

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS July 2006 No. OC404 TECHNICAL & SERVICE MANUAL Floor Standing Series PFFY R410A R407C Indoor unit [Model names] [Service Ref.] PFFY-P20VKM-E PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P32VKM-E PFFY-P40VKM-E PFFY-P40VKM-E CONTENTS 1. SAFETY PRECAUTION··························2 2. PART NAMES AND FUNCTIONS ··········6 3. -

Page 2: Safety Precaution

SAFETY PRECAUTION CAUTIONS RELATED TO NEW REFRIGERANT Cautions for units utilizing refrigerant R407C Do not use the existing refrigerant piping. Use liquid refrigerant to seal the system. The old refrigerant and lubricant in the existing piping If gas refrigerant is used to seal the system, the composition contains a large amount of chlorine which may cause the of the refrigerant in the cylinder will change and performance lubricant deterioration of the new unit. -

Page 3: Specification ·····································8

[3] Service tools Use the below service tools as exclusive tools for R407C refrigerant. Tool name Specifications Gauge manifold ·Only for R407C. ·Use the existing fitting SPECIFICATIONS. (UNF7/16) ·Use high-tension side pressure of 3.43MPa·G or over. Charge hose ·Only for R407C. ·Use pressure performance of 5.10MPa·G or over. - Page 4 Cautions for units utilizing refrigerant R410A Use a vacuum pump with a reverse flow check Do not use the existing refrigerant piping. valve. The old refrigerant and lubricant in the existing piping Vacuum pump oil may flow back into refrigerant cycle and contains a large amount of chlorine which may cause the that can cause deterioration of refrigerant oil etc.

- Page 5 [1] Cautions for service (1) Perform service after collecting the refrigerant left in unit completely. (2) Do not release refrigerant in the air. (3) After completing service, charge the cycle with specified amount of refrigerant. (4) When performing service, install a filter drier simultaneously. Be sure to use a filter drier for new refrigerant.

-

Page 6: Part Names And Functions

PART NAMES AND FUNCTIONS Indoor Unit Louver Air inlet Air outlet Vane Filter Damper Air outlet Louver Wired remote controller On the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button. Operation buttons ON/OFF button Set Temperature buttons Down... -

Page 7: Indoor Unit

Display “Sensor” indication Displayed when the remote controller sensor is used. Day-of-Week For purposes of this explanation, Shows the current day of the week. all parts of the display are shown as lit. During actual operation, only Time/Timer Display the relevant items will be lit. “Locked”... -

Page 8: Specification

SPECIFICATION 3-1. Specification Item PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E Power source 1-phase 220-240V 50Hz Cooling capacity Heating capacity Power Cooling 0.025 0.025 0.025 0.028 consumption Heating 0.025 0.025 0.025 0.028 Current Cooling 0.20 0.20 0.20 0.24 Heating 0.20 0.20 0.20 0.24... - Page 9 3-2. Electrical parts specifications Model Symbol PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E Parts name Thermistor (Room temperature Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k" TH21 detection) Thermistor (Pipe temperature Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k" TH22 detection / Liquid) Thermistor (Pipe temperature Resistance 0:/15k", 10:/9.6k", 20:/6.3k", 25:/5.4k", 30:/4.3k", 40:/3.0k"...

-

Page 10: Noise Criteria Curves

NOISE CRITERIA CURVES PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E FAN SPEED FUNCTION SPL(dB(A)) LINE FAN SPEED FUNCTION SPL(dB(A)) LINE COOLING COOLING High High HEATING HEATING Test conditions, Test conditions, Cooling : Dry-bulb temperature 27: Wet-bulb temperature 19: Cooling : Dry-bulb temperature 27: Wet-bulb temperature 19:... -

Page 11: Air Outlet Selection

AIR OUTLET SELECTION 220V 240V CN43 With this function, air comes out simultaneously from the upper and lower air outlets so that the room can be cooled or heated effectively. This function is set using the switch SWC on the address board. CN82 1 2 3 4 5 6 7 8 9 10 SW12... -

Page 12: Outlines And Dimensions

OUTLINES AND DIMENSIONS PFFY-P20VKM-E Unit : mm PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E INDOOR UNIT 4- [ 6 Hole Installation plate Indoor unit 46.5 46.5 Air out More than More than Air in 100mm 100mm Gas pipe [12.7(flared)1/2 Liquid pipe [6.35(flared)1/4 Air out... -

Page 13: Wiring Diagram

WIRING DIAGRAM PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E [LEGEND] SYMBOL NAME SYMBOL NAME SYMBOL NAME I. B FAN MOTOR (UPPER) INDOOR CONTROLLER BOARD TH23 PIPE TEMP. DETECTION/GAS CN32 CONNECTOR REMOTE SWITCH FAN MOTOR (LOWER) (0:/15k", 25:/5.4k") CN51 CENTRALLY CONTROL A. B VANE MOTOR... -

Page 14: Refrigerant System Diagram

REFRIGERANT SYSTEM DIAGRAM PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E Thermistor (Pipe temperature detection / Gas) TH23 Strainer (#50mesh) Gas pipe Thermistor (Pipe temperature detection / Liquid) TH22 Flare connection Liquid pipe Heat exchanger Linear expansion valve Strainer1 (#50mesh) Strainer2 (#50mesh) Strainer (#100mesh) -

Page 15: Trouble Shooting

TROUBLE SHOOTING 9-1. HOW TO CHECK PFFY-P20VKM-E PFFY-P32VKM-E PFFY-P25VKM-E PFFY-P40VKM-E Parts name Check points Room temperature Disconnect the connector then measure the resistance using a tester. thermistor (TH21) (Surrounding temperature 10:~30:) Liquid pipe temperature Normal Abnormal thermistor (TH22) (Refer to the next page for a detail.) 4.3k"~9.6k"... - Page 16 <Thermistor Characteristic graph> < Thermistor for lower temperature > Room temperature thermistor(TH21) Thermistor for Liquid pipe temperature thermistor (TH22) lower temperature Gas pipe temperature thermistor (TH23) Thermistor R =15k' ± 3% Fixed number of B=3480 ± 2% Rt=15exp { 3480( 273+t 15k' 9.6k'...

-

Page 17: Noise

<Output pulse signal and the valve operation> Output Output (Phase) Closing a valve : 1 Opening a valve : 4 The output pulse shifts in above order. 1. When linear expansion valve operation stops, all output phase become OFF. 2. At phase interruption or when phase does not shift in order, motor does not rotate smoothly and motor locks and vibrates. -

Page 18: Fan Motor

9-2. FAN MOTOR Check method of indoor fan motor (fan motor / control p.c.board) Notes · High voltage is applied to the connecter (CNMF1) for the fan motor. Give attention to the service. · Do not pull out the connector (CNMF1,2) for the motor with the power supply on. (It causes trouble of the control p.c.board) Self check... - Page 19 9-3. FUNCTION OF DIP SWITCH Operation by switch Effective Switch Pole Function Remarks timing Thermistor <Room temperature Built-in remote controller Indoor unit Address board detection> position Filter clogging detection Provided Not provided <At delivery> Filter cleaning 2,500hr 100hr Fresh air intake Effective Not effective 1 2 3 4 5 6 7 8 9 10...

- Page 20 Effective Switch Pole Operation by switch Remarks timing Address board <At delivery> (Option) Refer to 5. AIR OUTLET SELECTION. (Standard) Option outlet selector Standard SW11 Address board 1st digit Address can be set while the address SW12 SW11 unit is stopped. setting Address setting should be done when M-NET <At delivery>...

- Page 21 9-4. TEST POINT DIAGRAM 9-4-1. Indoor controller board PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E Power supply 1-2 : 220-240V AC FUSE 6.3A 250V CNMF1, CNMF2 FAN motor (upper) CNMF11-CNMF21 : DC280V CNMF23-1 : 15V DC CNMF25-1 : 0-6.5V DC CNMF27-1 : 0-15V DC...

- Page 22 9-4-2. Address board PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E Voltage selector Function setting SW12 SW11 1st digit address 2nd digit address Air outlet selection setting setting...

-

Page 23: Disassembly Procedure

DISASSEMBLY PROCEDURE PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E OPERATING PROCEDURE PHOTOS 1. Removing the panel Photo 1 (1) Push both sides of the upper part of the front grille and pull the front grille open, and then remove the front grille Push Push from the panel. - Page 24 OPERATING PROCEDURE PHOTOS Photo 3 2. Removing the indoor controller board and address board (1) Remove the panel. (Refer to 1.) (2) Remove the screw of the electrical cover, and then the electrical cover. (See Photo 3.) (3) Remove the screw of the ground wires connected to the indoor fan motor (lower), and then the ground wires.

- Page 25 OPERATING PROCEDURE PHOTOS Photo 5 4. Removing the vane motor (MV1) (1) Remove the panel. (Refer to 1.) (2) Remove the screws of the vane motor and pull out the vane motor. (See Photo 5.) (3) Disconnect the connector from the vane motor. Screw of vane motor 5.

- Page 26 OPERATING PROCEDURE PHOTOS 6. Removing the damper motor and the damper Photo 8 limit switch (1) Remove the panel. (Refer to 1.) (2) Remove the screws of the nozzle assembly (lower). (See Photo 8.) (3) Remove the drain hose from the nozzle assembly (lower) and pull out the nozzle assembly (lower) toward you.

- Page 27 OPERATING PROCEDURE PHOTOS 8. Removing the pipe temperature detection Photo 12 (liquid and gas) thermistors and room temperature thermistor (1) Remove the panel. (Refer to 1.) (2) Remove the screw of the electrical cover, and then the electrical cover. (See photo 3) (3) Remove the pipe temperature detection (liquid and gas) thermistors from the holders.

-

Page 28: Rohs Parts List

RoHS PARTS LIST 11-1. INDOOR UNIT ELECTRICAL PARTS AND FUNCTIONAL PARTS PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E... -

Page 29: Indoor Unit

11-1. INDOOR UNIT ELECTRICAL PARTS AND FUNCTIONAL PARTS Part number that is circled is not shown in the illustration. Q'ty/unit Symbol Part No. in Wiring Remarks Part name PFFY-P20/25/32/40VKM-E Diagram T7W E00 530 NOZZLE ASSEMBLY (UPPER) T7W E07 002 HORIZONTAL VANE (UPPER) T7W E06 002 HORIZONTAL VANE (LOWER) T7W E01 103... - Page 30 11-2. STRUCTURAL PARTS PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E 11-2. STRUCTURAL PARTS Q'ty/unit Symbol Part No. Part name in Wiring Remarks PFFY-P20/25/32/40VKM-E Diagram T7W E01 635 T7W E06 651 PANEL ASSEMBLY T7W E05 691 FRONT PANEL T7W E01 500 CATECHIN AIR FILTER...

-

Page 31: Indoor Unit

11-3. INDOOR UNIT HEAT EXCHANGER PFFY-P20VKM-E PFFY-P25VKM-E PFFY-P32VKM-E PFFY-P40VKM-E 11-3. INDOOR UNIT HEAT EXCHANGER Q'ty/unit Symbol in Wiring Remarks Part No. Part name PFFY-P20/25/32/40VKM-E Diagram T7W E00 031 HAIR PIN COVER T7W H56 480 INDOOR HEAT EXCHANGER T7W E01 031... - Page 32 HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN C Copyright 2006 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD New publication, effective Jul. 2006 Distributed in Jul. 2006. No. OC404 PDF 8 Specifications subject to change without notice. Made in Japan...